🧳 Agricultural Engineering

Important Concepts

Agricultural engineering

- It means application of engineering in agriculture.

- Father of Agricultural Engineering in India — Professor

Mason Vaugh. - Indian Society of Agricultural Engineers (ISAE) — 1960 at IIT, Kharagpur and presently it’s headquarter is at New Delhi.

- Agricultural Engineering consist of five major sub-disciplines:

- Farm Machinery and Energy in Agriculture

- Agricultural Structure and Process Engineering

- Dairy Engineering

- Irrigation and Drainage Engineering

- Soil and Water Conservation Engineering

Ergonomicsis science which gives relation between man, machine and working environments.

Status

- In Vision 2020 of ICAR – India requires total farm power of

2 KW/haand2300 kg/hagrain production. - It was expected to cross 2.02 KW/ha by 2018-19.

- In 2013-14 farm power available per ha was 1.84 kW/ha which is to increase 4.0 kW/ha by 2022.

- Out of the total energy produce in India, the percentage share of thermal power (62.7 per cent), hydro electrical power (12.6 per cent), nuclear power (1.9 per cent) and from renewable energy source is 23.1% include Small Hydro Project, Biomass Gasifier, Biomass Power, Urban & Industrial Waste Power, Solar and Wind Energy.

Biogas

- Biomass: mixture of Methane (

45-70 per cent) and Carbon dioxide (30-35 per cent). - Cattle dung: Water ratio for biogas slurry: 4 : 5 or 1 : 1.

- Buffaloes: 15 kg dung/day, bullocks or cows: 10 kg dung/day and calves: 5 kg dung/day.

- Suitable condition for biogas production - pH (7-8), temperature (35°C)

- Biogas calorific value – 4500 kcal/m3.

Wind Energy

- The speed required for operation of wind mill -

10 to 15 km/hr - Two types of wind mill (horizontal axis and vertical axis rotor)

- Horizontal axis rotor - axis of rotation is parallel to the direction of wind

- Multi blade

- Propeller - most commonly used is Sail type

- Vertical axis rotor axis of rotation is perpendicular to the direction of wind.

- Components of wind mill: tower, head, rotor, transmission gear, pump, generator.

Solar Energy

- Temperature of sun 5777°K

- Radiation range from sun, 0.4 mm to 2.6 mm maximum available range,

- <0.4 mm - ultraviolet radiation (8 per cent of total radiation)

0.4 - 0.7 mmvisible radiation (46 per cent)- …> 0.7 mm infra-red radiation (46 per cent)

- Solar Constant: solar radiation received per second by surface of unit area held normal to the direction of sun rays at mean earth-sun distance. Its value

1350W/m2 or1.94cal/s /m2. - Collection of solar radiation (three ways):

- By flat plate collector: temp range 40°C to 100°C

- Focusing or concentrating collector (>100°C)

- Photovoltaic cell (solar cell): directly convert solar energy in to electricity made of silicon separated by thin barrier with conversion efficiency is about 10 per cent.

- Potable water contained < 550ppm of salt, sea water contained 30,000-40,000 ppm of salt, ground water contained <2,000-3,000 ppm of salt.

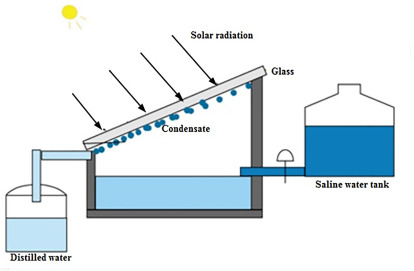

- Solar still-device converts saline water into portable water.

Energy from Agricultural Waste

- Thermo chemical process

- Direct combustion: burning of biomass in excess of air for steam generation

- Gasification: burning of biomass in limited supply of air at temp about 1100°C for production of

producer gas(CO + H2). - Pyrolysis: heating of biomass in absence of air (650-1100°C). Destructive distillation of biomass for production of

charcoal. - Liquefaction: rapid heating of biomass at low temp to convert it into liquid (acetic acid, acetone, menthanol, oils, chars)

- Biological process:

- Anaerobic digestion of biomass

- Fermentation

Ligninused as binder in briquette.- A briquette is a compressed block of coal dust or other combustible biomass material used for fuel and kindling to start a fire.

Modes of heat transfer

- Conduction: take place between particles of body that are direct contact with each other. E.g. solids

- Convection: direct movement of particles. e.g. fluids (liquid gas)

- Radiation: heat transfer in the form of electro magnetic waves without any medium.

Engine (Heat engine)

- External combustion (E.C.) engine: uses heat in the form of

steamgenerated outside in boiler, placed entirely separate from the cylinder. - Internal combustion (I.C.) engine: heat is generated inside the cylinder by burning of fuel

within cylinder.

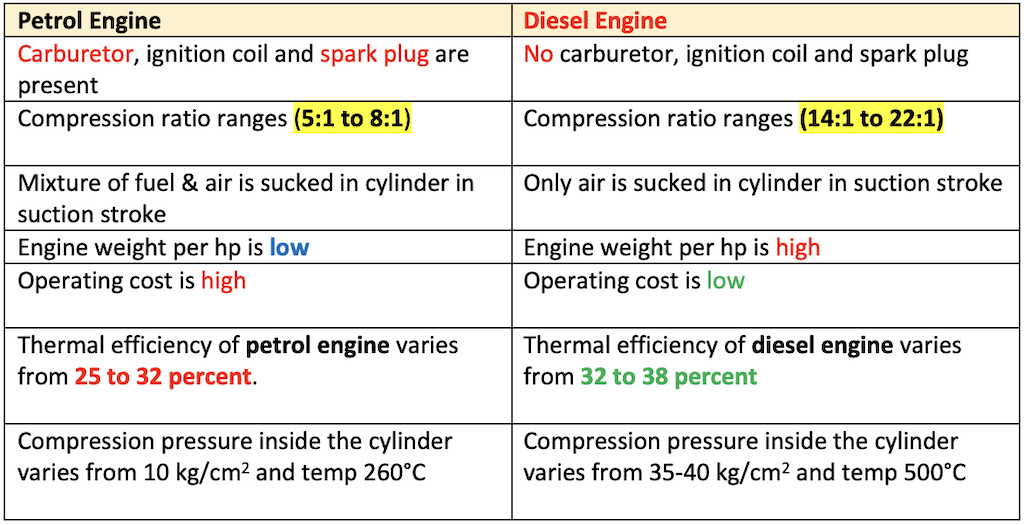

Two types of I.C. Engine (petrol Engine and Diesel Engine)

Petrol engine (Otto engine, spark ignition engine)

- Rapid explosion of air-fuel mixture within the cylinder, when it is ignited by spark.

- It is also called

constant volumecombustion. - Thermal efficiency of Petrol engine (n) is given by,

n = 1 - (1 /r)

- Where,

- r = compression ratio = total cylinder volume/clearance volume = V1/V2

- m = air constant = Cp/Cv = 1.4

- Cp = Sp. Heat at constant pressure

- Cv = Sp. Heat at constant volume

Diesel engine

- Combustion takes place by slow burning when the fuel is injected into highly compressed heated air contained in the cylinder.

- It is also called as

constant pressurecombustion. - Thermal efficiency of diesel engine (n) is given by,

n = 1 - (1/r)m-1 (pm - 1/m (p — 1))

- Where p = Cut off ratio

- In modern days, almost all tractors and power tillers are fitted with diesel engines.

Difference Between two and four stroke Engine

- The

strokein an engine is the distance covered by the piston from top dead center to the bottom dead center. - In simple words, stroke is the distance of cylinder between piston moves.

- If a piston moves 2 times in the cylinder, that means, engine is known as

two stroke engineand if it moves 4 times in afour stroke engine. - The crankshaft rotates

onetime between2 strokes. - The basic and main difference between two stroke and four stroke engine is that the crankshaft complete

one revolutionin one power stroke in2 stokeengine and completetwo revolutionin one power stork in4 strokeengine. IBPS AFO - Four stroke of the piston:

- Suction stroke

- Compression stroke

- Power stroke

- Exhaust stroke

- So the

2 strokeengine give high power compared to 4 stroke engine by the4 strokeengine is more fuel efficient. - There are many other differences which are given below:

- Firing Interval: The interval between successive power strokes in different cylinders of the engine.

- Bore (D): Diameter of the engine cylinder.

- Stroke (L):

- Linear distance travelled by the piston from top centre (TDC) to bottom dead centre (BDC).

- Stroke-bore ratio varies from 1 - 1.45 and for tractor is about

1.25.

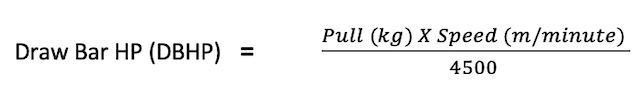

- Brake dynamometer measures brake or belt horse power and drawbar dynamometer measures drawbar horse power.

- Calorific value: The heat liberated by combustion of fuel is known as calorific value (kcal/kg).

- Octane number: measure of knock characteristics of a fuel, used for

petrol. - Cetane number:

Dieselfuels are rated according to cetane number, which is the indication of ignition quality of the fuel. - Air-fuel ratio in petrol engine (

15 : 1) for best result. - The process of preparing an air-fuel mixture away from the cylinder of an engine is called

carburetionand the device in which this process takes pace is called carburettor. Main functions of the carburettor are to mix the air and fuel thoroughly, to atomize fuel and regulate air-fuel ratio. - Turbocharger: It is a turbo-compressor driven by the exhaust gases of the engine to supply air under pressure to the cylinders of the engine.

- Governor is a mechanical device designed to control the speed of an engine within specified limits on tractor or stationary engines for (i) maintaining a nearly constant speed of engine under different load conditions (ii) protecting the engine and attached equipments against high speed; When the load is reduced or removed.

- For tractor engine-variable speed governor (e.g. centrifugal governor) and for stationary engine-constant speed governor are used.

- Governor hunting is erratic variation of speed governor when it over compensates for changes.

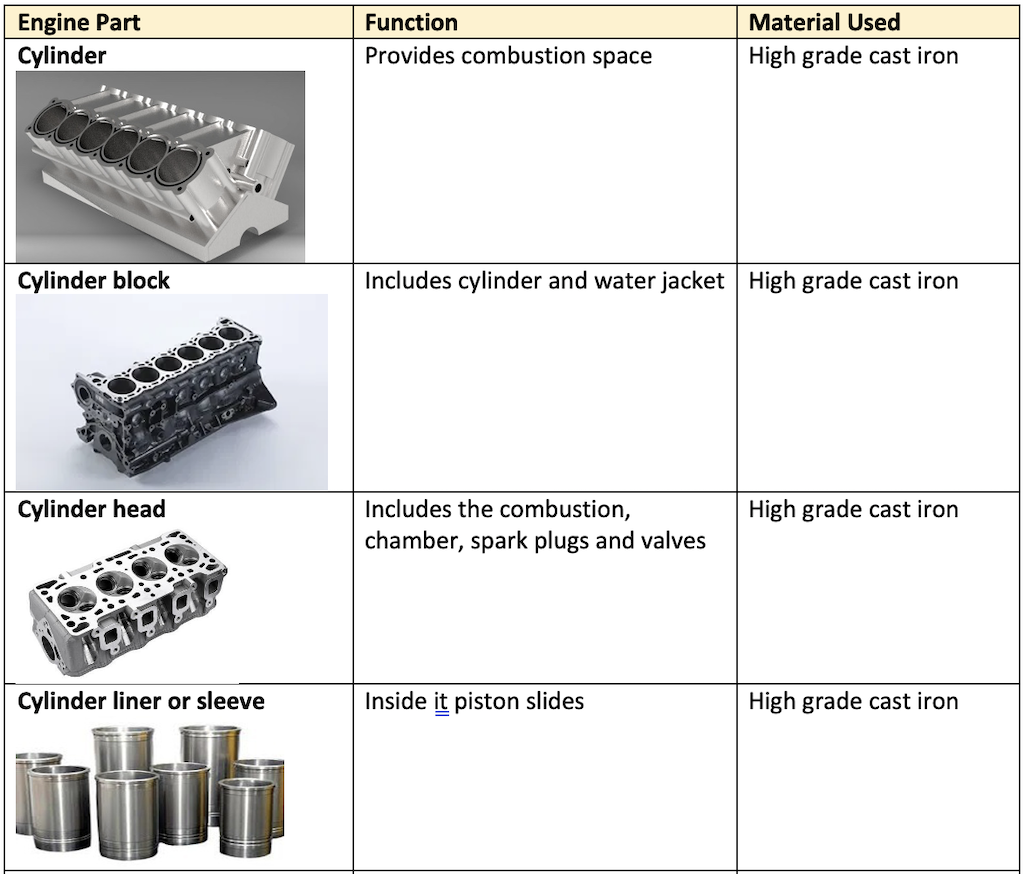

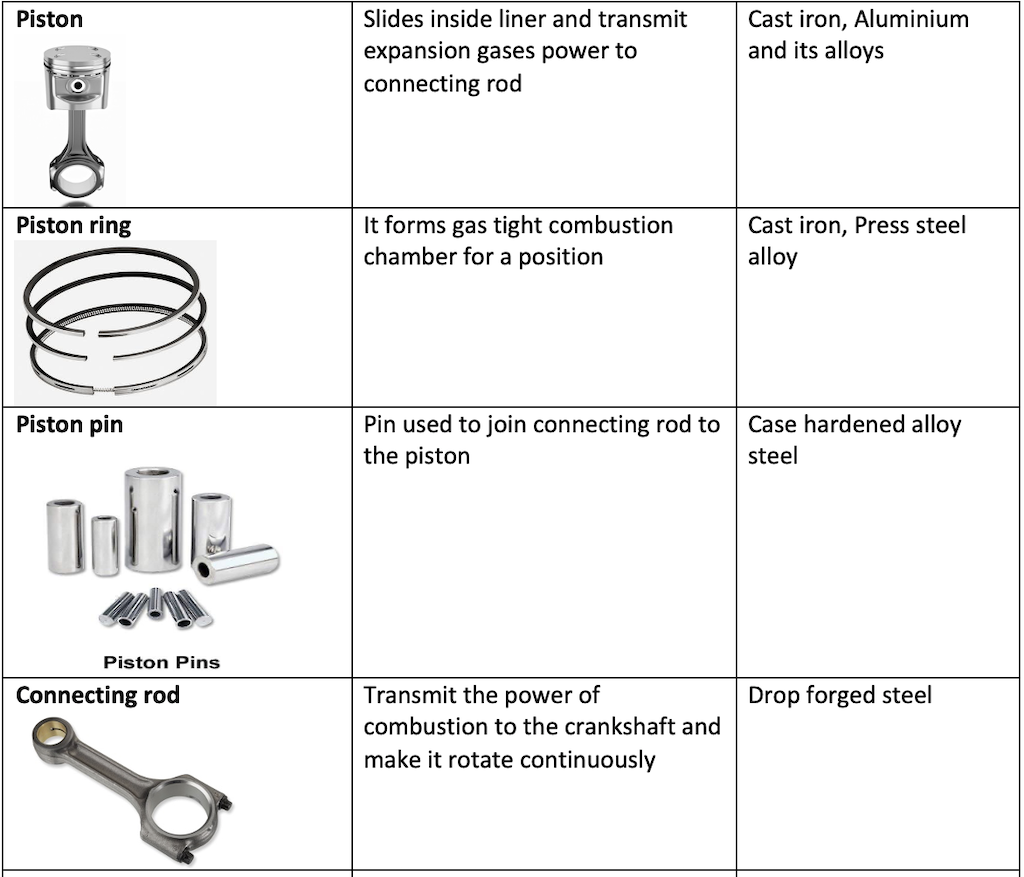

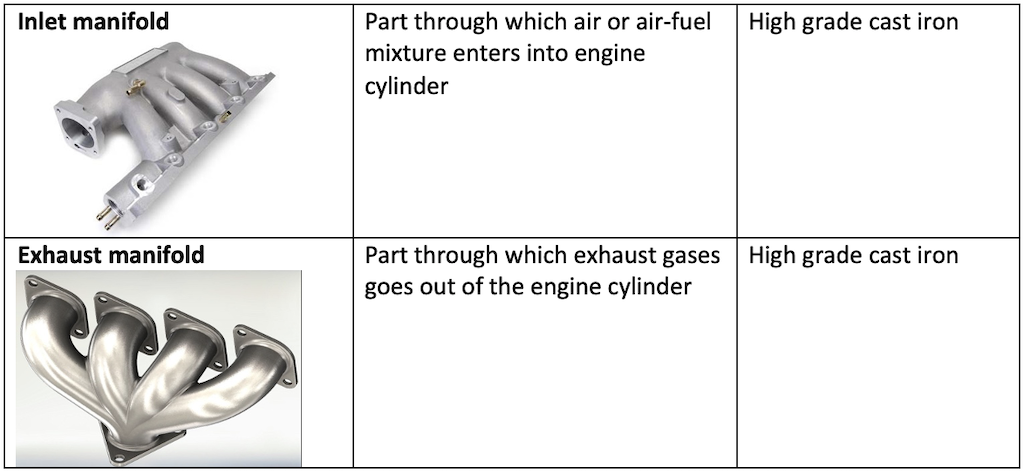

Material used for agricultural machinery

-

Ferrous material

- Cast iron (2.2 to 4.3 per cent carbon)

- Steel is alloy of Iron and Carbon (Low Carbon Steel: <0.25 per cent Carbon, Medium: Carbon Steel - 0.25 to 0.60 per cent Carbon, High Carbon Steel - 0.6 to 1.5 per cent Carbon).

-

Non-ferrous material

- Copper, Aluminium, Brass (Copper - 60 to 75 per cent + 30 to 40 per cent Zinc),

- Bronze (88 per cent Copper + 10 per cent Tin + 2 per cent Zinc)

-

Gears are used to transmit power at uniform angular velocity from one shaft to another.

- Spur gear: when used two shafts parallel to each other.

- Worm gear: two shaft right angle to each other but not intersecting to each other.

- Bevel gear: two shaft right angle to each other and can interact to each other.

- Helical gear: two shaft parallel to each other but inclined gears teeth.

Important Terms

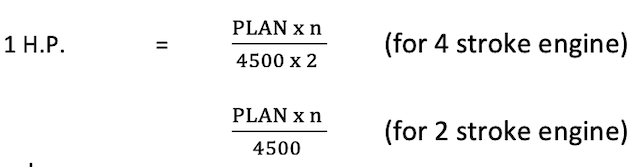

Horse power (HP)

- It is the rate of doing work.

- It is usually expressed in horse power.

- Conversion factors from work to power

- 4500 kg - m of work /minute = 1.0 hp

75 kg- m of work /second= 1.0 hp.- Roughly, 1.0 hp = 746 watts or

0.75 KW

- Where,

- P = Mean effective pressure (kg/cm2),

- L = Length of stock (meter),

- A = Area of cylinder (cm2),

- N = No. of revolution, n = no. of cylinders

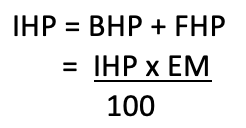

Indicated horse power (IHP)

- It is the power generated in the engine cylinder and received by the

piston. - It is the power developed in a cylinder without accounting frictional losses.

Brake horse power (BHP)

- It is the power delivered by the engine at the end of the

crankshaft. - It is measured by a dynamometer.

Thermal efficiency

- It is the ratio of the horse power output of an engine to the fuel horse power.

Mechanical efficiency

- Mechanical Efficiency (Per cent) =

BHP/IHP x 100 - Instrument used for power measurement is called dynamometer.

Power take-off horse power (PTO HP)

- The PTO horsepower is the amount of horsepower available for running implements with the tractor, like for example a bush hog.

- Most of the tractors have a Power Take Off Shaft, which is what connects to the implements to power them.

- The PTO hp is around 80-85% of tractor engine power (PTO-Power take off).

Frictional horse power (FHP)

- It is the power required to run the engine at a given speed without producing any useful work.

- It represents the friction and pumping losses of an engine.

- Engine loses some of its power while overcoming its own friction.

- This friction is known as the Friction Horse Power.

Agricultural engineering

- It means application of engineering in agriculture.

- Father of Agricultural Engineering in India — Professor

Mason Vaugh. - Indian Society of Agricultural Engineers (ISAE) — 1960 at IIT, Kharagpur and presently it’s headquarter is at New Delhi.

- Agricultural Engineering consist of five major sub-disciplines:

- Farm Machinery and Energy in Agriculture

- Agricultural Structure and Process Engineering

- Dairy Engineering

- Irrigation and Drainage Engineering

- Soil and Water Conservation Engineering

Ergonomicsis science which gives relation between man, machine and working environments.

Status

- In Vision 2020 of ICAR – India requires total farm power of

2 KW/haand2300 kg/hagrain production. - It was expected to cross 2.02 KW/ha by 2018-19.

- In 2013-14 farm power …

Become Successful With AgriDots

Learn the essential skills for getting a seat in the Exam with

🦄 You are a pro member!

Only use this page if purchasing a gift or enterprise account

Plan

Rs

- Unlimited access to PRO courses

- Quizzes with hand-picked meme prizes

- Invite to private Discord chat

- Free Sticker emailed

Lifetime

Rs

1,499

once

- All PRO-tier benefits

- Single payment, lifetime access

- 4,200 bonus xp points

- Next Level

T-shirt shipped worldwide

Yo! You just found a 20% discount using 👉 EASTEREGG

High-quality fitted cotton shirt produced by Next Level Apparel