🔥 Farm Power

Forms, Machineries

Forms of farm power

- Mobile

- Stationary

I. Mobile

- Human Power

- Animal Power

- Mechanical Power

Human Power

- A strong man can develop maximum power of about

75 watts(0.1 hp) for doing farm work. - The average human power availability in sustained working is as follows:

- Male: 60 watts (0.06 kW)

- Female: 48 watts (0.048 kW)

- Children: 30 watts (0.030 kW)

Animal Power

Draught animals

- Average pair of bullocks:

1 hp - The power available from draught animals is related to its body weight:

- Bullock: About 10% of the body weight

- Buffaloes: About 12% of the body weight

- Camels: About 18% of the body weight

- Donkey: About 32% of the body weight

- One pair of bullock can command about

2 ha land. - A power tiller (7.46 KW) can command about

5 ha land. - A tractor (26.1 KW) can command about

15 ha land.

Mechanical Power

- Tractor

- Power Tiller

- Self-propelled machines

- Combines

- Transplanters

- Reapers

- Sprayers

II. Stationary

- This kind of power can be provided by either the Stationary engines or the electric motors.

- Stationary oil engines can be used for pumping water, flour mill, cotton gins, sugarcane crusher, Thresher, Winnower etc.

Electrical Power

- Electrical power is used mostly in the form of electrical motors on the farms.

- Electrical power is used for water pumping, dairy industry, cold storage, farm product processing, fruit industry, poultry industry etc.

Renewable Energy

- It is the energy obtained from biomass, sun and wind.

- The energy obtained from these renewable resources, which are naturally replenished on a human timescale is used for many agricultural and domestic purposes.

- Examples: Used for lighting, cooking, water heating, water distillation, food processing, water pumping, diesel engine operation with supplementary fuel and electrical generation on small scale.

Farm Mechanization

- Farm mechanization is the application of engineering and technology in agricultural operation to do a job in a better way to improve productivity.

- When we talk about farm mechanization, it includes development, application and management of all mechanical aids for field production, water control, material handling, storing and processing.

- It includes not only big machines, but it is a need-based process which provide sufficient time gap for self-adjustment of various inputs without causing sudden impact of changes.

- Mechanization in farming operations is classified under following heads:

- Land levelling

- Seed bed preparation

- Sowing

- Weeding and interculture operations

- Fertilizer application and

- Harvesting and threshing

Land Levelling

- Land levelling is a measure used in surface irrigation, such as basin and furrow irrigation.

- It consists of:

- Preparing the irrigation plot in a way that no high and/or low spots disturb the uniform distribution of irrigation water on the field, and

- Ensuring the optimum slope for water movement across a field when irrigation.

Importance

- Levelling results in more efficient irrigation and, if fertigation and chemigation are applied, in more efficient use of fertilizers and pesticides.

- In an unlevelled field, high spots might not be covered by irrigation water, and the dissolved nutrients and/or pesticides might percolate unused into the soil.

- In case of low spots, water and the dissolved nutrients and chemicals might accumulate there and create zones of water logging and nutrient or pesticide accumulation.

- This in turn will disturb soil aeration and water uptake by crops.

- In either case, the uniformity of the crop cover is disturbed, and yields might decrease.

- Benefits of land levelling:

- Higher yield

- Better weed control

- Larger farming area

- Faster seeding/less work

- Better use of water

Equipments for land levelling

- For land development, bullock drawn implements, have been developed and are commercially available such as:

- Scoop

- Buck scraper

- U-leveler

- Float leveler

- Laser leveler

Soil Scoop

- Soil scoops are used for excavating ditches, clearing drains and doing cut and fill jobs in land leveling.

- The angle of the cutting blade varies from 12° to 15° angle.

Leveling board - bullock drawn

- It is a wooden board of length 2.0 m, width 0.4 m and thickness 0.3 m provided with side wings, hitching braces and handle.

- The following can also be used:

- 2-wheel tractors using harrows and leveling boards

- 4-wheel tractor using rear mounted tractor blades or drag

- By a 4-wheel tractor with a laser-controlled bucket

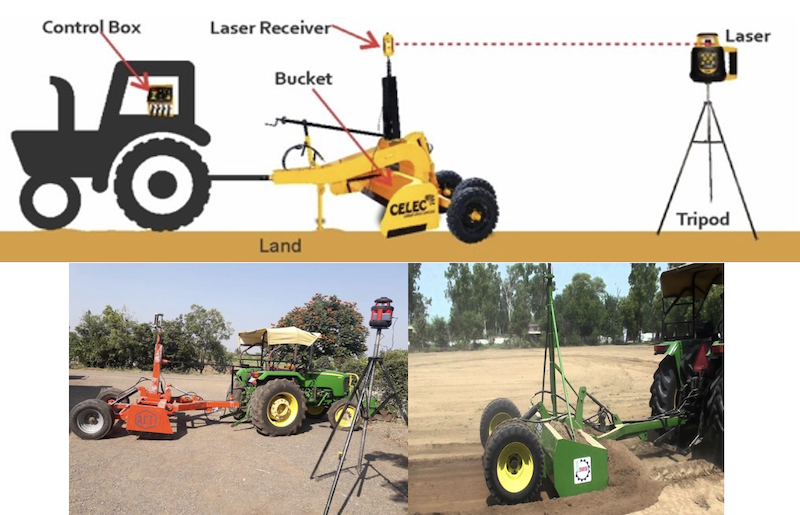

Laser Land Leveling

- Laser leveling systems are commonly used in agricultural applications in Australia, Japan and the United States.

- Increasingly, laser guided systems are being used in lesser developed country contexts as well.

- Using laser leveling results in a much more level field because accuracy can be improved by as much as 50% compared with the other systems.

- A laser transmitter transmits a laser beam, which is intercepted by the laser receiver mounted on the leveling bucket.

- The control panel mounted on the tractor interprets the signal from the receiver and raises or lowers the bucket. This way the soil gets shifted to the right places to make the entire field level.

Seed bed preparation

- Seed bed preparation is done to provide a suitable environment for the seeds to germinate.

Seed Drill

- Drilling – Dropping of seeds in furrow of a predetermined dimension, at a predetermined distance and depth, covering with soil followed by compacting is known as drilling.

- Seed drill and Horse-hoe was introduced by

Jethro Tull. - Seed drill is a machine used for placing the seeds in a continuous stream in furrows at uniform rate and at controlled depth with an arrangement of covering the seeds with soil.

- In manually metered seed drills a person drops the seeds in the furrows, in mechanically metered seed drills a mechanical device called

seed metering mechanismis used to meter the seeds. - Seeds are sown/dropped in 5 cm depth of soil and 5 cm far from fertilizer.

- Seed drill performs the following functions

- To carry the seeds

- To open furrows at uniform depths

- To meter the seeds

- To deposit the seeds in furrows in an acceptable pattern

- To cover the seeds and compact the soil around the seed.

- Seed Cum Fertilizer drill

- Seed drills fitted with fertilizer dropping attachments are called seed-cum-fertilizer drills.

- They deliver both the seeds and fertilizers simultaneously in an acceptable pattern.

- Seed metering mechanism

- The mechanism which picks up seeds from the seed box and delivers them in to the seed tube is called seed metering mechanism.

- Seed metering mechanism may be of several types:

- Fluted feed type

- Internal double run type

- Cup feed type

- Cell feed type

- Brush feed type

- Auger feed type

- Picker wheel type and

- Star wheel type

- Usually seed metering mechanism is provided at the bottom of the box.

Fluted feed typeseed metering mechanism is most commonly used in seed drill.- Calibration of Seed Drill:

- Laboratory testing of a seed drill to determine the rate of seed delivery is called calibration of a seed drill.

- Size of seed drill = no. of furrow openers x distance between two furrow openers

- Sowing area in 1 circle of seed drill = Size of drill x p x D

- Types of furrow openers:

- The furrow openers are provided in a seed drill for opening a furrow.

- The seeds travel through the seed tube and reach the furrow.

Planter

- Planter is a sowing equipment used for sowing those seeds which are larger in size and cannot be handled by seed drills.

- Row to row and plant to plant spacing is maintained in a planter.

- Potato planter, maize planter, cotton planter are the commonly used equipment.

Potato planter (Automatic seed dropping)

- The fertilizer and pesticide can also be placed simultaneously.

- It can plant in 2-4 rows. Field capacity is 6000-14000 potatoes/hr.

Potato planter (Semi-automatic)

- The fertilizer and pesticide can also be placed simultaneously.

- It can plant in 2-4 rows. Field capacity is 0.15-0.35 ha/hr.

Manual rice planter

- The row to row spacing is 200 mm.

- It can cover 0.25 ha/day.

- Two men labour are required one for pulling the unit and another for transporting the mat seedlings.

- The machine consists of a seedling tray, six number of forks

Weeding and Intercultural

- The tillage operations that are carried out in the standing crop are called after tillage.

- Collectively, the cultivation practices taken up after sowing of crop is called inter-cultivation.

- It is otherwise called as after operation or inter-culturing.

- It facilitates good aeration, and better development of root system.

Khurpi

- Khurpi is the most versatile hand hoe for removal of weeds.

- It takes 300-700 man-hours to cover one hectare, depending upon crop, soil and weed infestation.

Hand Hoe

- Hand hoe is the most popular manually operated weeding tool used in the farm.

- It consists of an iron blade and a wooden handle.

- The operator holds the handle and cuts the soil with the blade to a shallow depth of 2-3 cm thereby weeds are cut and soil is stirred.

- The handle is short (30-40cm long) and hence the operator uses the tool in bending posture.

- The coverage is 5-7 cents per day.

Long Handle Weeders

- Hand hoes exert greater strain on the operator because of the short handle which necessitates the operator to do weeding job in bent posture.

- To avoid this nowadays long handles are used in hoes and hence they are called as long handle weeders.

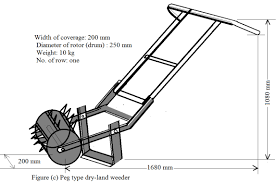

- The popular long handle weeders available are a) star type weeder b) peg type weeder.

- These weeders are also called as dry land weeders since they are used in dry lands.

- Star type weeder: It is suitable for weeding in dry lands. It can be used in garden lands also when the soil moisture is low (10-15%). Star wheel is designed for loamy soils. The operating width of the blade is 120 mm. The coverage is 0.05 ha/day.

- Peg type weeder: It is suitable for weeding in dry lands. It can be used in garden lands also when the soil moisture is low (10-15%). Peg type wheel is designed for clayey soils. The operating width of the blade is 120 mm. The coverage is 0.05 ha/day.

- Star type weeder: It is suitable for weeding in dry lands. It can be used in garden lands also when the soil moisture is low (10-15%). Star wheel is designed for loamy soils. The operating width of the blade is 120 mm. The coverage is 0.05 ha/day.

Wheel hoe

- The coverage is 0.05 ha/day.

Cultivators

- It is an implement used for inter cultivation with laterally adjustable tines or discs to work between crop rows.

- This can be used for seed bed preparation and for sowing with seeding attachment.

Types of cultivator

- Disc cultivator (It is a cultivator fitted with disc)

- Rotary cultivator (It is a cultivator with tines or blades mounted on a power-driven horizontal shaft)

- Tine cultivator (It is a cultivator fitted with tines having shovels)

- Functions

- It stirs the soil and breaks the clods.

- The tines fitted on the frame of the cultivator comb the soil deeply in the field.

- Destruction of weeds is the primary function of a cultivator.

- Types of cultivator

- Depending upon the type of power available for the implements, the cultivator can be classified as:

- Tractor drawn

- Animal drawn

- Depending upon the type of power available for the implements, the cultivator can be classified as:

- Types of tractor drawn implements:

- The tractor drawn implement maybe Trailed or Mounted.

- Mounted Cultivator:

- Tractors fitted with hydraulic lift operate the mounted type cultivators.

- A rectangular frame of angle iron is mounted on three point hydraulic linkage of the tractor.

- The cross members carry the tines in two staggered lines.

- For actual cutting of the soil, different types of shovels and sweeps are used.

Harvesting and Threshing

- It is the operation of cutting, picking, plucking, digging or a combination of these operations for removing the crop from under the ground or above the ground or removing the useful part or fruits from plants.

Threshing

- Threshing is a process detaching grain from ear heads or from the plants with using impact or wearing (rubbing) action.

- Most common threshing machines are olpad thresher, power thresher, threshing by combiner etc.

- Size of thresher = size of cylinder x width of winnowing part

- Basic components of power thresher

- Feeding unit

- Threshing unit (concave, cylinder on which beaters/spike/rasp bar/ hammer are mounted)

- Cleaning unit with oscillating sieves, fan, air sucking duct (aspirator)

- Separating unit

- Collecting unit

- Types of thresher (based on cylinder)

- Rasp bar - shearing action: for paddy

- Spike tooth — impact and shear action

- Hammer mill — impact action

- Syndicator type — cutting action

- Loop thresher: for paddy

Combine

- Function:

- Cutting the standing crops

- Feeding the cut crops with the threshing unit

- Threshing the crops

- Cleaning the grains freeing it from straw

- Collecting the grains in container

- Types:

- Self-propelled type: This has got its own dependent engine and size varies from 2-4 m.

- PTO driven type: This combine is pulled by a tractor and the power requirement of the combine may be taken on 8 HP/m width of cut for pulled type machine and 12 HP/m width of cut for self propelled machines.

- Threshing efficiency: the threshed received from all outlets with respect to total grain input expressed as percentage by mass.

- Concave clearance: Clearance between beaters or cylinder tip and concave.

- Chaff cutter: machine used for cutting fodder for animal feed. NABARD 2021

Duffee formulais used for determine the capacity of chaff cutter.

Forms of farm power

- Mobile

- Stationary

I. Mobile

- Human Power

- Animal Power

- Mechanical Power

Human Power

- A strong man can develop maximum power of about

75 watts(0.1 hp) for doing farm work. - The average human power availability in sustained working is as follows:

- Male: 60 watts (0.06 kW)

- Female: 48 watts (0.048 kW)

- Children: 30 watts (0.030 kW)

Animal Power

Draught animals

- Average pair of bullocks:

1 hp - The power available from draught animals is related to its body weight:

- Bullock: About 10% of the body weight

- Buffaloes: About 12% of the body weight

- Camels: About 18% of the body weight

- Donkey: About 32% of the body weight

- One pair of bullock can command about

2 ha land. - A power tiller (7.46 KW) can command about

5 ha land. - A tractor (26.1 KW) can command about

15 ha …

Become Successful With AgriDots

Learn the essential skills for getting a seat in the Exam with

🦄 You are a pro member!

Only use this page if purchasing a gift or enterprise account

Plan

Rs

- Unlimited access to PRO courses

- Quizzes with hand-picked meme prizes

- Invite to private Discord chat

- Free Sticker emailed

Lifetime

Rs

1,499

once

- All PRO-tier benefits

- Single payment, lifetime access

- 4,200 bonus xp points

- Next Level

T-shirt shipped worldwide

Yo! You just found a 20% discount using 👉 EASTEREGG

High-quality fitted cotton shirt produced by Next Level Apparel