🌬 Plant Protection Equipment

Sprayer and Dusters

Need for Plant protection equipment

- These days more fields remain covered under crops for longer duration of time due to multiple cropping and various methods employed for increasing the efficiency of crop production.

- Because of these reasons, it has become necessary to use pesticides and fungicides for controlling pests and diseases.

- These chemicals are applied in the form of spray and dust.

- There are many types of dusters and sprayers that are available for plant’s protection.

Sprayers

- It is a machine to apply fluids in the form of droplets.

- Now, the sprayers are used for multiple purposes.

Purposes of sprayers

- Application of fungicides to avoid/minimize fungal diseases

- Application of herbicides to remove weeds

- Application of insecticides to control insect pests

- Application of micro-nutrients on the plants

Types of Spray

- Based up on the volume of liquid handled, sprayers may be classified into:

- High volume spray (

more than 400 liters /ha) IBPS AFO - Low volume spray (

5 to 400 liters/ hectare) - For aerial dose:

15-75 liters/ha(used in fruit crops)

- For ground dose:

100 – 120 liters/ha(used in field crops) - Ultra-low volume sprayer (ULV) spray (

less than 5 liters /ha). One hectare of crop can be treated in around 2.5 hour. - ULV spraying can be defined as plant protection in which total volume of liquid applied amount to a few milli litre per acre. It is mainly used in aircraft.

- High volume spray (

- Most commonly used sprayers are low volume and ultra-low volume sprayer.

- Nozzles on field sprayers have angle ranges of 60 to 90° but pressure nozzles have smaller angles.

Commercial Sprayer

- Sprayers are of three types:

- Manually operated

- Engine operated

- Airplane operated

- Manually operated sprayers are classified as follows:

- Hand atomizer type

- Stirrup pump type

- Knapsack type

- Bucket type

- Hand compression sprayer

- Rocket sprayer

- Foot sprayer

- Engine operated sprayer is classified as follows:

- Knapsack mist sprayer duster

- Power sprayer

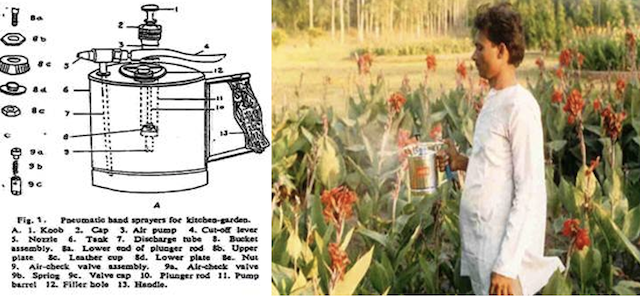

Hand Atomizer

- This sprayer is also ideally suited for home gardens and small fields.

- It consists of a container of 0.5 to 3.5 lit capacity a built in air pump, pressure gauge, nozzle and flow cut-off lever. The tank is to be filled with 3/4th volume.

- The pump is operated to build pressure in the tank of 0.15-0.3 kg/cm2.

- When the flow cut-off lever is pressed, the fluid passes through the nozzle and spraying is done.

- The application rate ranges from 45 to 100 litres/ha.

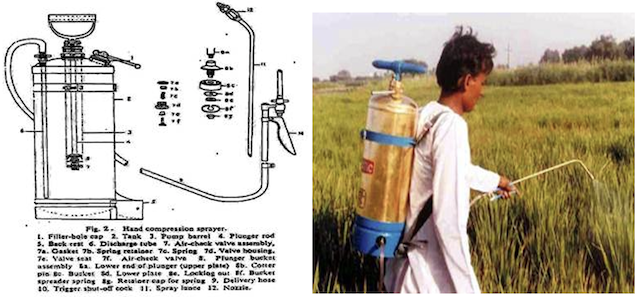

Hand compression sprayer

- It is suitable for applying chemicals for field crops and lawns.

- The pump is operated to pump air in to the tank to build pressure up to 2.0 — 3.5 kg/cm2.

- When the flow cut-off lever is pressed, the fluid passes through the nozzle and spraying is done. The sprayer is carried on the shoulder of the operator.

- The application rate ranges from 45 to 100 liters /ha.

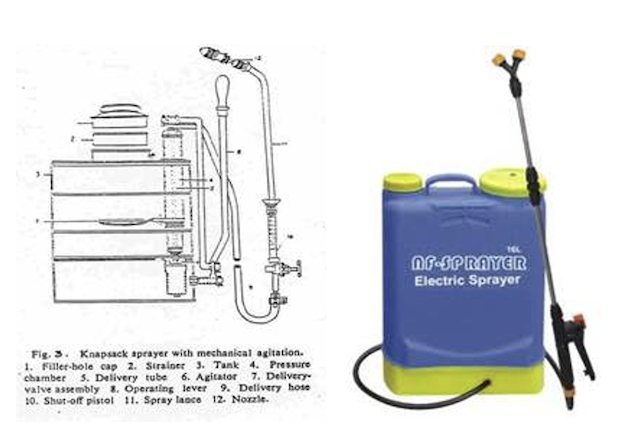

Knapsack sprayer (hand operated)

- This sprayer is suitable for applying chemicals to several field crops.

- It has a flat or bean-shaped tank of 10-15 liters capacity.

- A hydraulic pump fitted inside the tank, a handle to operate the pump, agitator, fitter, delivery hose, and spray gun with nozzle and flow control lever.

- The tank is made of either brass or PVC material.

- The pressure developed in these sprayers depends on the pump and varies from 3 to 12 kg/cm2 the application rate is 500 lit/ha.

- The coverage is 0.5-1.0 ha/day.

Rocker sprayer

- Rocker sprayer is mainly used for spraying fruit trees in orchards, coconut and areca nut trees, flower gardens, and cotton and tapioca fields, the pump builds up a pressure up to 14-18 kg/cm2 which facilitates the use of the sprayer for tree spraying.

- The output of the sprayer is 70-90 lit/hr with one nozzle.

- Coverage is about 1.5 ha/day.

Foot or pedal operated sprayer

- The foot or pedal sprayers, as they are commonly called, consist of a plunger assembly, stand, suction hose, delivery hose, spray gun with a nozzle etc.

- Constant pedaling is required for continuous spray.

- It develops a pressure of 17-21 kg/cm2.

- The discharge rate with one nozzle is 110-135 L/hr and coverage is 1.0 ha/day.

Power Sprayer

- Power sprayers are operated usually with internal combustion engines.

- It can be powered by a 3 HP engine or electric motor.

- The pressure pump is operated by a small power unit ensuring a constant steady pressure.

- They are operated at pressure from 20 to 55 kg/cm2.

- These machines are usually portable type.

- A power sprayer consists of the following parts:

- Prime mover

- Tank

- Agitator

- Air chamber

- Pressure gauge

- Pressure regulator

- Strainer

- Boom

- Nozzles

Pumps for Spraying

👉🏻 There are three types of pumps that are used for spraying:

- Piston or plunger pump (well suited for high pressure spraying. The volumetric efficiency of this pump is as high as 90%)

- Rotary pump (used for low pressure sprayers)

- Centrifugal pump (pump working on high speed having high volume discharge)

Duster

- Duster is a machine to apply chemical in dust form.

- Dusters make use of air streams to carry pesticides in finely divided dry form on the plants.

- Types of duster:

- Plunger type

- Knapsack type:

2.5 to 5 kg

- Rotary type

- Power operated duster

- Plunger type

Need for Plant protection equipment

- These days more fields remain covered under crops for longer duration of time due to multiple cropping and various methods employed for increasing the efficiency of crop production.

- Because of these reasons, it has become necessary to use pesticides and fungicides for controlling pests and diseases.

- These chemicals are applied in the form of spray and dust.

- There are many types of dusters and sprayers that are available for plant’s protection.

Sprayers

- It is a machine to apply fluids in the form of droplets.

- Now, the sprayers are used for multiple purposes.

Purposes of sprayers

- Application of fungicides to avoid/minimize fungal diseases

- Application of herbicides to remove weeds

- Application of insecticides to control insect pests

- Application of …

Become Successful With AgriDots

Learn the essential skills for getting a seat in the Exam with

🦄 You are a pro member!

Only use this page if purchasing a gift or enterprise account

Plan

Rs

- Unlimited access to PRO courses

- Quizzes with hand-picked meme prizes

- Invite to private Discord chat

- Free Sticker emailed

Lifetime

Rs

1,499

once

- All PRO-tier benefits

- Single payment, lifetime access

- 4,200 bonus xp points

- Next Level

T-shirt shipped worldwide

Yo! You just found a 20% discount using 👉 EASTEREGG

High-quality fitted cotton shirt produced by Next Level Apparel