🏠 Storage

Process before storage and Storage Structure

- Concrete is usually defined as mixture of cement, sand coarse aggregate (gravel and water in correct proportions and thoroughly mixed so that upon setting, it forms rock-like mass).

- Slump test is performed to measure the

plasticity of concrete. - Curing of concrete is the process of

strengtheningit through hydration. (7 days) - Mortar: Mixture of cement sand and water, or lime, sand and water.

- Compressive strength of concrete ranging between 300 to 700 kg/cm2.

- Seasoning of wood is primary rid of all the surplus sap and moisture, to avoid decay or affected by fungus.

- Rankine formula/Airy formula used for determination in shallow bins.

- Janssen formula used for determination lateral pressure in deep bins.

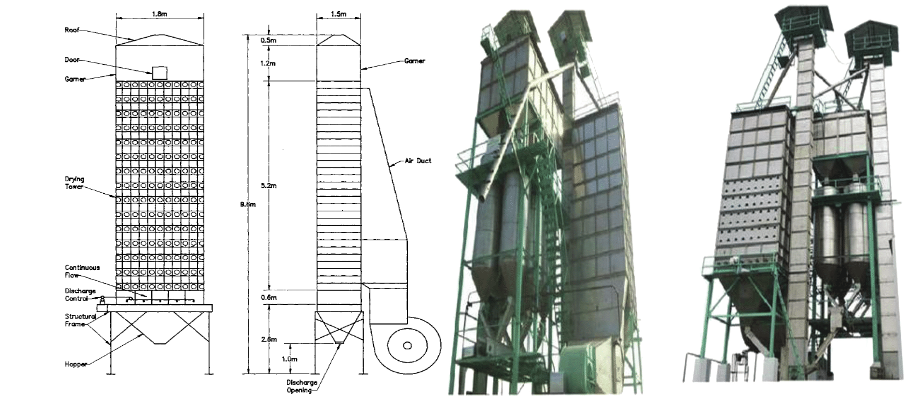

LSU continuous flow dryeris most commonly used in India developed at Louisiana state University Baton Rouge, USA in1949.- Aero and hydrodynamic properties such as Drag Coefficient and Terminal Velocity of agricultural products are important and required of air and water conveying systems and separation equipment.

- Fourier law is used for heat transfer through conduction.

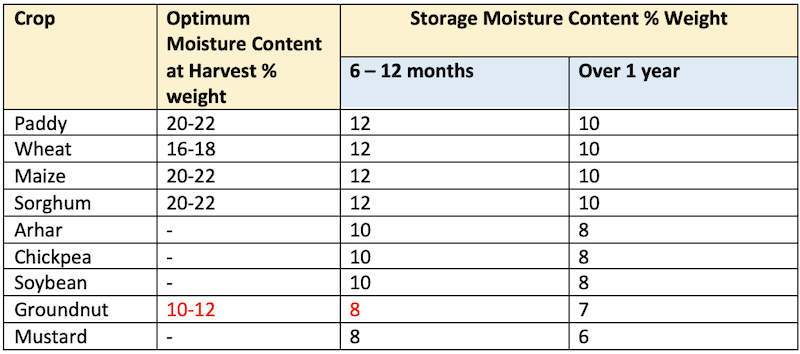

- Moisture content (M.C.) of some of the crops at harvest and for safe storage

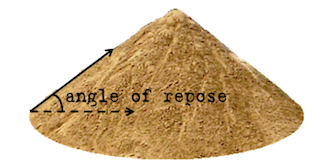

- Angle of repose is the angle between the base and the slope of the cone formed on a free vertical fall of the granular material to horizontal plane. Tilting top drafting table and circular platform is used for measurement of angle of repose.

- Refrigeration - process of removal heat from a space at a temperature lower than the surrounding temperature. The principle of refrigeration is based on second law of thermodynamic.

- Latent heat of fusion of water at atmospheric condition is

80 kcaland Latent heat of vaporisation of water at atmospheric condition is540 kcal. - Scalping refers to the removal of few large particles in an initial process, e.g. scalper.

- Cleaning process generally means the removal of foreign and undesirable matter from desired grain/products as much as possible to ensure its purity, e.g. cleaner. Cleaning is done on the basis of size, weight and length of impurities.

Types of Impurities

- Large impurities - straw panicles, soils, stones, bag strings, iron parts

- Small impurities - dust, sand soil particles, weed seeds, insects and small stones

- Same as about grains - empty grains

Cleaning of impurities

- Light impurities (in wt.) removed by Aspiration or by sieving.

- Small, large & heavy impurities removed by Sieving

- Same size but heavy removed by Gravity separation

- Same size & weight impurities are not easily removed

- Weed seeds are removed by sieving

- Iron particles are removed by Gravity separation or Electromagnetic separation method.

Air Cleaning Machine (ASM)

- Clean the grain based on size and weight

- ASMs perform absorption, main scalping and grading.

- Absorption - Light wt. materials are removed

- Main scalping - Grain of other crops removed by screen due to grain shape differences

- ASMs have 2-8 screens.

- 3 screens clean small purities, but 4 screens used for desired and more purity.

Types of ASM

- Open double sieve cleaner - open, 2 oscillating sieve, 300-400 rpm of transmission shaft.

- Self-cleaning sieve - wooden frame, compartment (20cm x 20cm or more), 2 rubber bolls of 1.9 cm and 3.2 cm.

- Single action sieve

- Single action Aspirator cleaner - one fan or blower, closed type of cleaner.

- Double action Aspirator cleaner

- Single Drum type cleaner - developed by Japan, for stone separation by gravity.

- Double Drum type cleaner

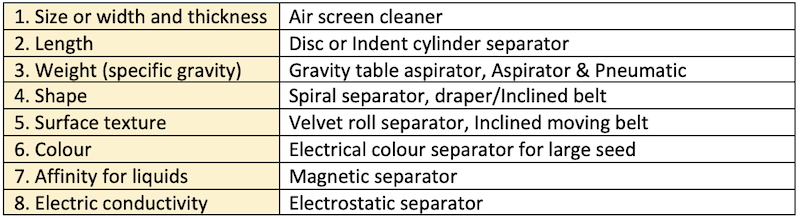

- Separation refers to the sorting of cleaned products (grain) according to various physical characteristics i.e on the basis of size, shape, weight, EC, density, texture and colour, from inert material and other crop seeds, e.g. separator.

Principle of Separation of Grain/Seed

Grading

- Grading refers to the removal or separation of smaller (under size), over size (bigger) and shriveled grains from main/pure/well fitted (healthy) grain of the same crop depending upon the various commercial values and other uses, e.g. grader.

- More effective in mixture of grains or mixture of same crop

- Based on length and shape both (Cleaning + Separation).

- ASM used for grading of grains due to air current by fan.

GRADERS

- Same length but different thickness → Rotating graders

- Different length but same thickness → Trieurs

- Different length and different thickness both → Rotating graders + Trieurs combination

- Mixture of different varieties with same length & thickness → Grading Impossible

Rotating Grader

- Also called as “Grading reels”

- It grades on the basis of

thickness.

Trieurs

- A rotating indented steel cylinder machine for grading of grains on the basis of

length. - It has thousands of pockets (2-8mm) for uploading mixed grain (short & long).

- During rotation of cylinder (50 rpm), each pocket upload with grains and short grains fall from higher point and long grains fall first from pockets.

Sieves

- Small broken grains separated, when mixed with short medium but rounded variety.

Dryers

- Drying refers to removal of moisture from grains and other products to a predetermined level equilibrium to the surrounding air (10 to 12 per normally).

- Recirculatory Batch Dryer (PHTC dryer, developed from UT’ Khadagpur 2 tons capacity).

- Louisiana State University Dryer (popular in India & USA)

- Size of rectangular bins - (1) 1.2m x 1.2m (2) 1.5m x 1.5m (3) 1.8m x 1.8m (4) 2.1m x 2.1m

- Air distribution from ‘V’ shaped channels.

- Conditioning is the process of maintaining uniform moisture and temperature of stored agriculture produce by moving a small amount of air through it.

- Moisture measurement method:

- Oven dry method → 130°C ± 2°C for 1 hrs

- Chemical method → use of

Calcium Carbide

- Equilibrium Moisture Content (EMC): When a grain (product) exposed to a continuous supply of air at a constant temperature and humidity under partial pressure, grain losses the moisture content from surrounding air, until the vapour pressure of grain and air come to equal.

Henderson equationis most popular equation for determining of EMC.- EMC curve or Isotherm: a plot of EMC and ERH (Equilibrium Relative humidity) at a particular temperature (25°C).

- Grain isotherm is commonly in

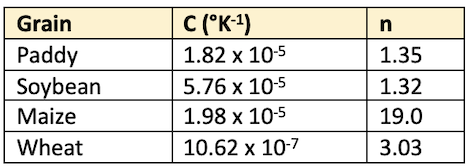

S-shaped. - Henderson equation of grain isotherm:

1-RH = e-CTMn

- Where,

- RH = Relative humidity,

- C = grain constant (Kelvin),

- T = temperature of air (°K),

- M = EMC of grain on dry basis (per cent),

- n = grain constant (dimensionless)

- Psychrometric chart is graphical representation of thermodynamic properties of air at 1 atm pressure. The thickness of grain in thin-layer drying is normally up to grain to 15 cm.

- The deep bed dry drying grain depth is ranges from >15 to < 45 cm.

- Grain handling mechanical devices:

- Belt conveyor — longer distance

- Bucket elevator — very efficient for vertical conveyance (<50 meter)

- Screw conveyor — used for short distance

- Triple point of water lie at

0°Cand 4.59 mm of mercury at this point three phase of water viz. solid, ice, liquid water and water vapourcoexistat equilibrium.

Storage

- Grain is generally stored either in bags or in bulk.

- A combined system of bag-cum-bulk storage is also practiced in some parts of the country.

- In villages the bulk storage system is more common than the storage in bags which is considered to be a practicable method of storing grain in the government godowns as well as in trade.

- Main three types of storage structures for storage of grains.

- Traditional storage structures

- Improved storage structures

- Modern storage structures

- Farm Silos

Traditional Storage Structures

- In this types of storage structures the grain is generally stored in bulk.

- This types of storage structures having generally capacities between 1 to 50 tonnes.

- The storage of grain is generally done in one of the following storage structures in the different rural and urban regions of India in bulk as well as in bag storage.

- Morai (Eastern & Southern India)

- Bukhari

- Kothar

- Mud kothi

- Kuthla, Muda (Bihar)

- Kanaj (Karnataka, Maharashtra)

Improved Storage Structures

- Improved storage structures are the storage structures for storage of food grains.

- In this type of storage structures there are some improvements made in traditional storage structures.

- This type of storage structures having a higher storage capacity and long-term storage of food grains than traditional storage structures.

- Improved type of storage structures having capacities is generally 1.5 to 150 tonnes.

- The storage of grain is generally done in one of the following storage structures in the different rural and urban regions of India in bulk, bag as well as bag and bulk storage.

Pusa bin

- Pusa bin is like other traditional storage structures made of mud.

- To make the storage structure moisture proof a plastic film is used in all the inner sides of the bin.

Brick and cement bin

- These type of storage structures are very strong and effect of seasons on these is minimum.

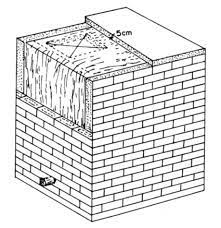

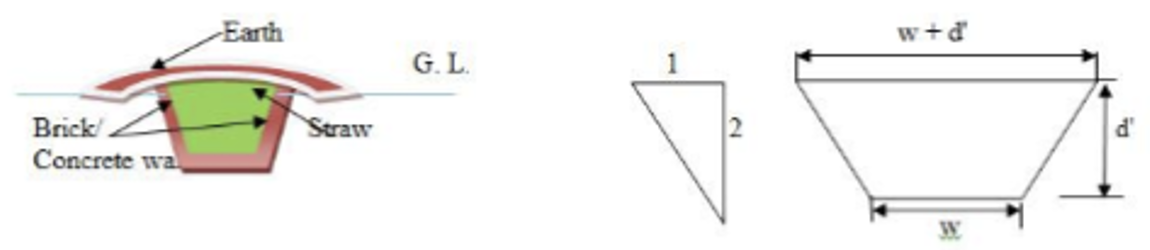

Bunker Storage

- These type of storage structure is used for long term storage and a larger volume of grains storage.

‘CAP’ Storage structures

- The word ‘CAP’ is used for

Cover and Plinth, plinth from the bottom and cover from the top. - This type of open storage is considered as transit storage and serves the purpose of storage of food grains in bags for short period.

Modern Storage Structures

- In India, for larger volume of food grains are to be stored in bulk is ‘silo’ and conventional godowns (Shed) designed for bagged storage.

- The godowns side walls are of brick or stone masonry and sloped roofing in asbestos or Corrugated Galvanized Iron (CGI) sheets over steel trusses.

Silosare constructed from steel or reinforced concrete.- There are a cluster of adjoining silos in any modern large/ capacity processing plant.

- The modern permanent storage system should be selected for the safe keeping of stored grains and other products.

- The modern storage structures should be selected on the basis of first on quality and then on cost considerations.

Types of modern storage structures

- Silo type of storage structures

- Silos/bins are classified into two groups depending upon the relative dimensions of the container. These are classified as,

- Deep bins

- Shallow bins

- Silos/bins are classified into two groups depending upon the relative dimensions of the container. These are classified as,

Shallow bins

- A bin whose relative dimensions are such that the plane of rupture meets the grain surface before it strikes the opposite side.

- Squat silos are comes under shallow bins. A squat silo has a wall height to diameter ratio 0.5 or even less. Squat silo can compete with sheds for low-cost quality storage.

Deep bins

- A bin whose relative dimensions are such that the plane of rupture meets the opposite side before it emerges from the grain.

- Vertical Silos are comes under this type of storage structures.

- There are two types of vertical silos

- Flat bottom vertical silo and

- Hopper bottom vertical silo

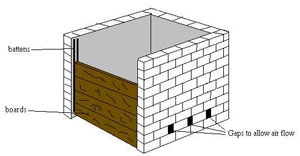

Shed

- Generally, a horizontal sheds have been used to provide low-cost, large volume storage.

- For storing grains and other products a very large volume sheds have also been constructed by Central Warehousing Corporation.

Farm Silos

- Farm silos is a farm structure used to store and protect the animal fodder so that it is preserved in an ideal condition for farm animals.

- Animal fodder is cut and packed in the air tight silo to allow a partial fermentation to occur.

- The storage fodder is known as

silage. - There are two types of farm silos

- Tower silos

- Horizontal silos

Tower silos

- Cylindrical Shape and made of masonary, wood or metal

- Cost of construction is comparatively much higher than that of horizontal type.

- Loading of animal fodder is difficult.

- Mechanical loader or a large capacity of blower is essential.

Horizontal silos

- In horizontal silos pit type, bunker type and trench or stake type of storage structures used for storage of animal fodder.

- There are surface as well as below ground (underground) types of storage structures used on most of dairy farms as temporary and permanent storage structures for silage.

- The spoilage of silage and dry matter losses of these silos ranges between 20 to 30 percent.

Pit Silos

- Permanent pit silo is a circular deep well which is lined all around the side, and sealed from bottom, so that water may not rise in to it.

- Made in areas where the soil is deep and the water table is very low.

- Made of bricks, stones or concrete, and either cement or lime can be used as a binding material.

- A 22.5 cm thick wall will be used satisfactory up to 15 meter depth.

- The entire surface which is coming in contact with the silage should be plastered to make it smooth, air tight and water tight.

- Simple roof is made over the silo to protect the silage from sun and rain.

- Corrugated metal sheet dome or half pitch roof with ample overhang on all the sides are most economical and provide more space for filling.

- Stairs may be built along with wall for removing silage from the silo.

- The diameter of a silo is usually limited to 6 m and its depth is kept 2 to 3 times that of diameter.

- When the silo is opened for removing the silage, nobody should enter till the gases are removed.

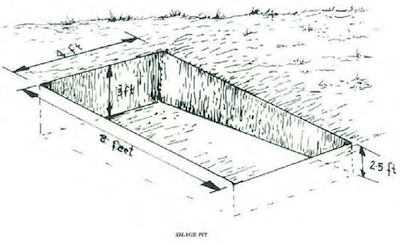

Trench Silos

- Unlined trench silo can be made easily without involving any investment on building materials such as brick, cement and sand.

- Unlined silos give more spoilage and are likely to have caved side walls due to excessive rain and tend to become muddy at the bottom. So, lined trench silos are therefore become popular.

- The walls of the trench silos can be lined with brick, concrete or cement plaster with reinforcing wire mesh.

- If possible, the silo should be roofed.

- Drains should be made around trench to intercept surface water.

- To facilitate drainage, it is desirable to locate the trench silo on slopping ground.

- Capacity is depending on size of herd and number of day the silage is fed in a year.

- It is always economical to construct only one trench silo, even if it is quite larger.

- Sidewalls are given generally 33 per cent slope.

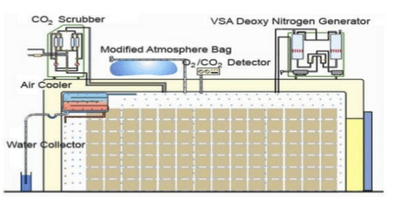

Modified Storage Systems

- MAP (or MAS) is modified atmosphere packaging in which we can change the composition of gas in a container with a fixed gas mixture.

- After doing so we do not have any control over the process and the gas composition changes inevitably in the container due to activities such as product respiration.

- Controlled Atmosphere Packaging (CAP) (or CAS) we have control over the storage atmosphere (which is in fact air tight).

- As the desired gas composition (i.e.

high carbon dioxide levelandlow oxygen level) changes due to metabolic activity of fruits and vegetables, it is possible to add fresh air or nitrogen to achieve pre-determined (desired) gaseous composition. - The normal composition of air is 78% nitrogen and 21% oxygen, with the balance made up of carbon dioxide (0.035%), other gases and water vapour.

- An increase in the proportion of carbon dioxide and/or a reduction in the proportion of oxygen within specified limits maintains the original product quality and extends the product shelf life.

- The plate type heater exchange is mostly used in large sizes dairies.

- Brine-Concentrated CaCl or NaCl solution is used for cooling water or milk directly.

- Solid CO2 is called Dry ice.

- Two most commonly used refrigerators are Ammonia and Freon-10.

- Concrete is usually defined as mixture of cement, sand coarse aggregate (gravel and water in correct proportions and thoroughly mixed so that upon setting, it forms rock-like mass).

- Slump test is performed to measure the

plasticity of concrete. - Curing of concrete is the process of

strengtheningit through hydration. (7 days) - Mortar: Mixture of cement sand and water, or lime, sand and water.

- Compressive strength of concrete ranging between 300 to 700 kg/cm2.

- Seasoning of wood is primary rid of all the surplus sap and moisture, to avoid decay or affected by fungus.

- Rankine formula/Airy formula used for determination in shallow bins.

- Janssen formula used for determination lateral pressure in deep bins.

LSU continuous flow dryeris most commonly used in India developed at Louisiana state …

Become Successful With AgriDots

Learn the essential skills for getting a seat in the Exam with

🦄 You are a pro member!

Only use this page if purchasing a gift or enterprise account

Plan

Rs

- Unlimited access to PRO courses

- Quizzes with hand-picked meme prizes

- Invite to private Discord chat

- Free Sticker emailed

Lifetime

Rs

1,499

once

- All PRO-tier benefits

- Single payment, lifetime access

- 4,200 bonus xp points

- Next Level

T-shirt shipped worldwide

Yo! You just found a 20% discount using 👉 EASTEREGG

High-quality fitted cotton shirt produced by Next Level Apparel