🚋 Tillage Implements

Primary and Secondary Tillage Implements

Primary Tillage Implements

- The initial major soil working operations designed to plough the soil deeply to reduce soil strength, cover plant materials and rearrange aggregates is called primary tillage.

- Tractor draws implements include mould-board ploughs, disc ploughs, heavy duty disk harrows, subsoiler, chisel ploughs etc.

Ploughs

- Plough was invented during 2900 BC.

- The main implement which is used for primary tillage is Plough used for ploughing operations.

- Ploughing is the primary tillage operation which is performed to cut, break and invert the soil partially or completely.

- Iron plough was invented by James Small.

- Normal ploughing under primary tillage operation is usually done up to 15 cm depth.

- Vertical suction/clearance: Adjustment for depth control in M.B. plough.

- Horizontal suction/Side clearance: This suction helps M.B. plough to cut the proper width of furrow slice.

- Through clearance: It is perpendicular distance between point of share and lower position of the beam of the plough.

- Pull: total force required to pull an implements.

- Draft: Horizontal component of the pull, parallel to line of motion.

- Side draft: Horizontal component of the pull, perpendicular to line of motion.

- Unit draft: Draft per unit area.

- Effective field capacity: It is the actual area covered by implements, based on its total time consumed and its width (ha/hr).

- Theoretical field capacity: It is the theoretical area covered by implements, based on its total time consumed and its width (ha/hr).

- Field Efficiency = (Effective field capacity/Theoretical field capacity) x 100

- Soil pulverization is quality of work in terms of soil aggregates and clod size. This is measured by

Penetrometer. - Cohesion: Force of attraction between

similarparticles.(e.g. soil and soil) - Adhesion: Force of attraction between

dissimilarparticles (e.g. soil and metal) - Gathering: Whenever a plough works round a strip of ploughed land, it is said to be gathering.

- Casting: Whenever a plough works round a strip of un-ploughed land, it is said to be casting.

- Certain important terms related with ploughing of land:

- Furrow: A trench formed by an implement in the soil during the field operation.

- Furrow slice: The mass of soil cut, lifted and thrown to one side.

- Furrow wall: An undisturbed soil surface by the side of a furrow.

- Crown: The top portion of the turned furrow slice.

- Back furrow: A raised ridge left at the centre of the strip of land when ploughing is started from centre to side.

- Dead furrow: An open trench left in between two adjacent strips of land after finishing the ploughing.

Types of plough

👉🏻 The different type of ploughs are as follows:

- Indigenous plough

- Mould board plough

- Disc plough

- Chisel plough

- Sub soiler

- Rotary plough

List of Primary Tillage Implements

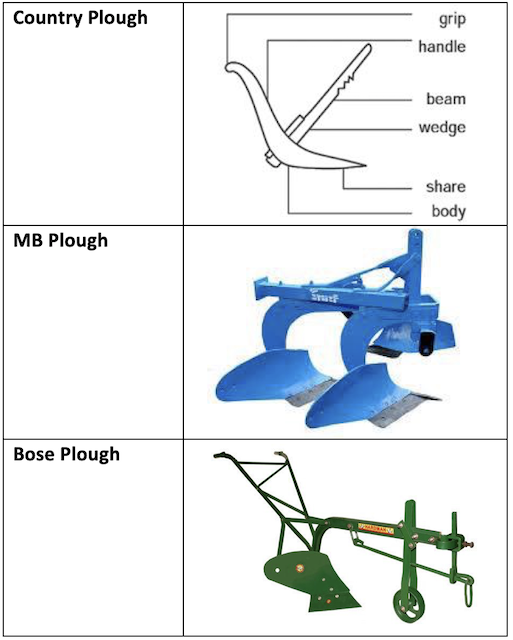

Country Plough (Indigenous Plough)

- Main parts of a plough:

- Body

- Share

- Shoe

- Beam

- Handle

- Body: It is the main frame to which the shoe, beam and handle are attached.

- Share: It is a narrow steel bar attached to the upper surface of the shoe longitudinally along the centre line and the handle are generally attached to the body of the plough.

- Types:

- Slip share

- Slip nose

- Shin

- Bar point

- Material of Share: The shares are made of chilled cast iron or steel. The steel mainly contains about 0.70 to 0.80% carbon and about 0.50 to 0.80% manganese besides other minor elements.

- Shoe: The share is attached to the shoe which penetrates into the soil and breaks it open. The shoe also helps in stabilizing and balancing the plough while in operation.

- The plough is provided with a wooden beam and a handle.

- Important points:

- It is an animal drawn plough.

- It penetrates into the soil and breaks it open. It forms V shaped furrows with

15-20 cmtop width and 12-15 cm depth. - It can be used for ploughing in dry land, garden land and wetlands.

- The size of the plough is represented by the width of the body and the field capacity is around

0.4 ha per day of 8 hours. - Working efficiency of desi plough is 0.32 hp/day.

Sub Soiler

- All plough and Sub-soiler (open up hard span below 40 cm depth) are the primary tillage implements.

- Infiltration of soil is with hard pan can be increased by subsoiling.

- Sub soiler works up to the depth of

45 - 75 cm.

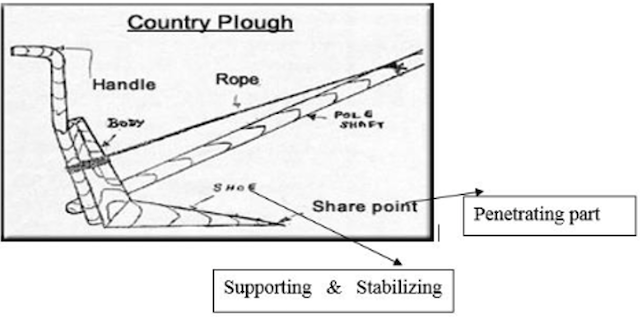

Mould Board Plough

- Mould board is an implement which is used for ploughing. AFO-2021

- Mould Board ploughs are available for animals, power tiller and tractor operation.

- While working, a mould board plough does four jobs namely:

- Cutting the furrow slice

- Lifting the furrow slice

- Inverting the furrow slice and

- Pulverizing the furrow slices

- Capacity

1.5-2.0ha/day.

Disc Plough

- It is a plough which cuts, turns and in some cases breaks furrow slices by means of separately mounted large steel discs.

- A disc plough is designed with a view to reduce friction by making a rolling plough bottom instead of sliding plough bottom.

- Disc plough is used for primary tillage and it is specially used where M.B. Plough is not useful such as hard and dry soil.

- In some model disc plough is designed to operate as 2, 3 or 4 bottoms, by adding or removing sub beams the sub beam assemblies according to requirement.

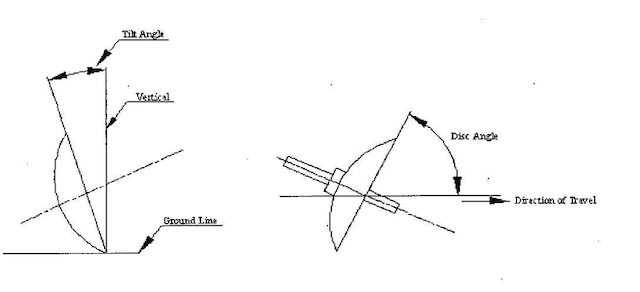

- Disc: It is a circular, Vertical Disc plough revolving steel plate used for cutting and inverting the soil.

- Disc angle:

- It is the angle at which the plane of the cutting edge of the disc is inclined to the direction of travel.

- Usually the disc angle of good plough varies between

42 to 45°.

Width of cutof plough is increases by increasing disc angle.- Tilt angle:

- It is the angle at which the plane of the cutting edge of the disc is inclined to a vertical line.

- The tilt angle varies from

15° to 25°for a good plough.

- Scraper: It is device to remove the soil that tend to stick to the working surface of disc.

Secondary Tillage Implements

- Tillage operations performed after primary tillage to create proper soil tilth for seeding and planting are called secondary tillage.

- These operations are lighter and finer operations performed on the soil after primary tillage operations.

- Harrows, cultivators, sweeps, cloud crushers, levelers, bund formers, puddlers, roller and hoes are come under secondary tillage implements.

Harrow

- A harrow is an implement that cuts the soil to a shallow depth for smoothening and pulverizing the soil as well as to cut the weeds and to mix materials with soil.

- It is an implement used to break the clods after ploughing, to collect trash from the ploughed land and to level the seed bed.

- Harrow is used for harrowing, which is a secondary tillage operation, which pulverizes, smoothens and packs the soil in seed bed preparation and to control weeds.

- Types of harrows used in India

- Disc harrow

- Spring tooth harrow

- Spike tooth harrow

- Blade harrow (Bakhar)

- Triangular harrow

- Zig-zag harrow

- Bodela

- Guntaka

- Bindha

- Rotary tiller

- Other harrows

Disc Harrow

- It is a harrow, which performs the harrowing operation by means of a set of rotating discs, each set being mounted on a common shaft.

- Disc harrow is found very suitable for hard ground with full of stalks and grasses.

- It cuts the lumps of soil, clods and roots.

- Types of disc harrows:

- Depending upon the source of power, disc harrows are of two types:

- Tractor drawn (depending upon the disc arrangements, disc harrows are divided into two classes — Single action and Double disc.

- Animal drawn

- Single action disc harrow: Harrow with two gangs placed end to end which throws the soil in opposite directions.

- Double action disc harrow:

- A disc harrow containing two or more gangs, in which a set of one or two gangs follow behind the set of the other one or two, arranged in such a way that the front and back gangs throw the soil in opposite directions.

- Thus the entire field is worked twice in each strip.

- It maybe of two types: Tandem and off-set.

- Tandem Disc Harrow

- Off-set Disc harrow

- Parts of Disc Harrow:

- Disc: Concave disc 35-70 cm diameter

- Gang: It is an assembly of concave discs mounted on a common shaft with spools in between.

- Spool or Spacer: The flanged tube, mounted on the gang axle between every two discs to retain them at fixed position laterally on the shaft is called Spool or Spacer.

- The other parts are Gang bolt, Gang angle, Gang control lever, Spools or Spacer, Bearings, Transport wheels, Scraper and Weight Box.

- Tractor drawn harrow has a capacity of

2.5 ha/day.

Power harrow – tractor drawn

- A power harrow tills the soil maintaining the same profile of the field.

- It pulverizes the upper and lower layer of soil without turning them upside down and thus it forms a good seed bed as well as good soil mulch.

- It consists of two horizontal cross bars fitted with rigid pegs which reciprocate taking power from the PTO of a tractor.

- The pegs are spaced 200 mm wide and are staggered with respect to each cross bar.

- The two bars move in opposite directions and hence the implement is dynamically balanced.

- The oscillating pegs break the clods and pulverizes the soil to a fine tilth.

- The width of the operation is 2000 mm and the field capacity is around 1.5 ha/day.

Rotary Tiller (Rotavator)

- The rotary tiller or rotary cultivator is widely considered as the most important implement as it provides fine degree of soil pulverization.

- It is directly mounted to the tractor and operated.

- The rotor is operated at

180 – 200 rpm. - Capacity is

0.5 ha/hr. - Types of blades used in rotary tillers

- ‘L’ type blade: Works well in trashy conditions. More effective in cutting weeds and but do not pulverize the soil much.

- Twisted blade: Suitable for deep tillage in relatively clean grounds, but clogging and wrapping of trashes on the tynes and shafts needs frequent cleaning.

- Straight blade: Employed on mulchers designed mainly for secondary tillage.

- The benefits of the rotary tiller are:

- effective pulverization of soil ensures good plant growth

- cutting and mixing of stubbles and roots and mixing with soil and

- leveling of the field

Other Important Implements

- Basin lister: Prevent runoff and form basins.

- Sweep cultivator: Harvesting groundnut and used in stubble mulching.

- Potato digger: Used to harvest potatoes

- Groundnut digger: Used to harvest groundnut.

- Maize Sheller: Used to separate maize grains from cobs.

- Seed dressing drum: Used to treat the seed with chemicals.

- Hand gin: Used to separate lint from seed cotton.

- No-till planter: Used for sowing. AFO 2017

Primary Tillage Implements

- The initial major soil working operations designed to plough the soil deeply to reduce soil strength, cover plant materials and rearrange aggregates is called primary tillage.

- Tractor draws implements include mould-board ploughs, disc ploughs, heavy duty disk harrows, subsoiler, chisel ploughs etc.

Ploughs

- Plough was invented during 2900 BC.

- The main implement which is used for primary tillage is Plough used for ploughing operations.

- Ploughing is the primary tillage operation which is performed to cut, break and invert the soil partially or completely.

- Iron plough was invented by James Small.

- Normal ploughing under primary tillage operation is usually done up to 15 cm depth.

- Vertical suction/clearance: Adjustment for depth control in M.B. plough.

- Horizontal …

Become Successful With AgriDots

Learn the essential skills for getting a seat in the Exam with

🦄 You are a pro member!

Only use this page if purchasing a gift or enterprise account

Plan

Rs

- Unlimited access to PRO courses

- Quizzes with hand-picked meme prizes

- Invite to private Discord chat

- Free Sticker emailed

Lifetime

Rs

1,499

once

- All PRO-tier benefits

- Single payment, lifetime access

- 4,200 bonus xp points

- Next Level

T-shirt shipped worldwide

Yo! You just found a 20% discount using 👉 EASTEREGG

High-quality fitted cotton shirt produced by Next Level Apparel