🥛 Milk

Composition of Milk, Parameters, Methods of Milking

Which of the following statment is wrong?

- Milk is the lacteal secretion of the mammary glands of animals. It is obtained generally from the cow or the buffalo during the period following at least 72 hours after calving or until the milk is colostrum free.

- Milk is a white opaque fluid in which fat is present as an

emulsion, protein and some mineral matters incolloidal suspension, and lactose together with some minerals and soluble proteins intrue solution.

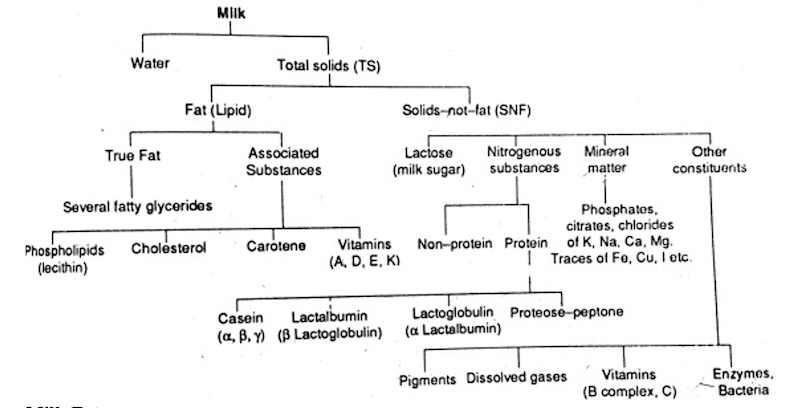

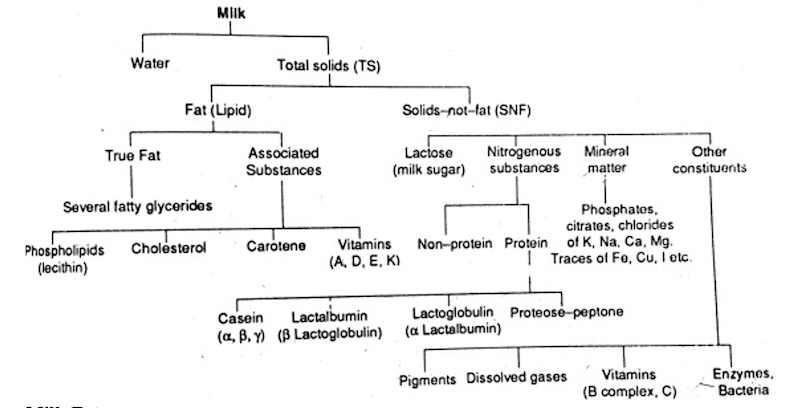

Composition of Milk

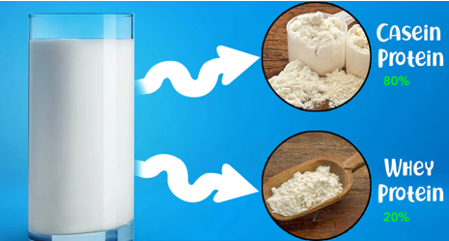

- Milk proteins composition:

80% Casein Proteinand20% Whey Protein. - Lactose of milk can be digested by lactase enzyme in human body.

- Milk is sweet because of presence of

lactosesugar. - All 22 minerals considered essential to the human diet are present in milk.

- Milk is a poor source of Iron and Vitamin C.

- The fat-soluble vitamin A, D, E, K in milk depends on their availability in the feed.

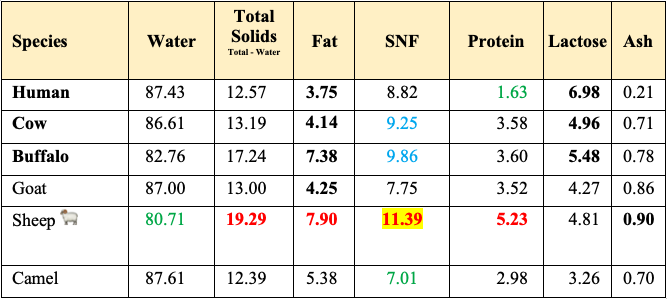

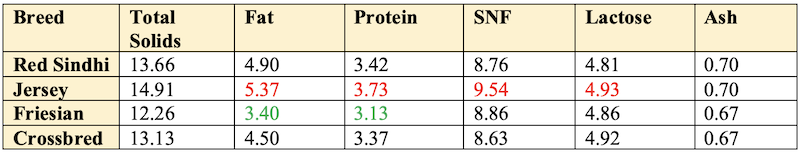

- Composition of milk depends on spices, breed and feed.

Avg. composition of milk of different mammals (in %)

Avg. composition of milk of some important milch breeds of cows (in %)

- The development of the mammary gland is known as Mammogenesis.

- The process of producing and secreting milk from the mammary gland is known as Lactation.

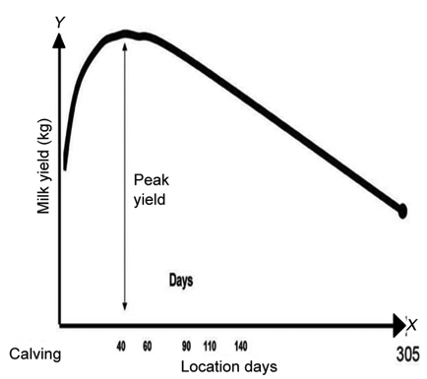

- The graphical representation of the rate of milk secretion during lactation is called Lactation Curve.

- Milk production increases rapidly following parturition and replace a peak in 2 to 4 weeks where it remains for a short period and then gradually declines.

- Lactation length/period:

- This indicates the duration or time the female animal produces the milk after giving birth.

- The time interval between the dates of calving to the date of drying the animal expressed in days.

- It depends on type of animals species.

- It varies from 180 to 305 days.

- Dry period: The time interval between the date of drying off the cow to the date of next calving.

- Lactation yield: The amount of milk produced during complete lactation period.

- West average (W.A.): It is Total milk yield. Of a lactation (kg or Lt) divided by lactation period (in days). [3000/250 = 12 litres per day]

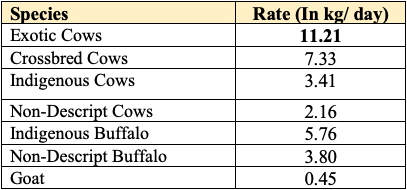

Average Milk Yield Rate in India

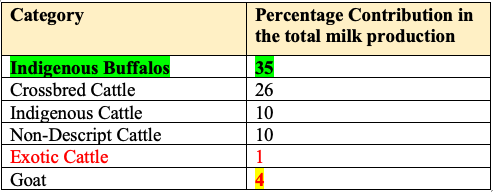

Species Wise Milk Contribution in India

- Galactopoiesis: Maintenance of Lactation is known as Galactopoiesis.

Milk Hormones

-

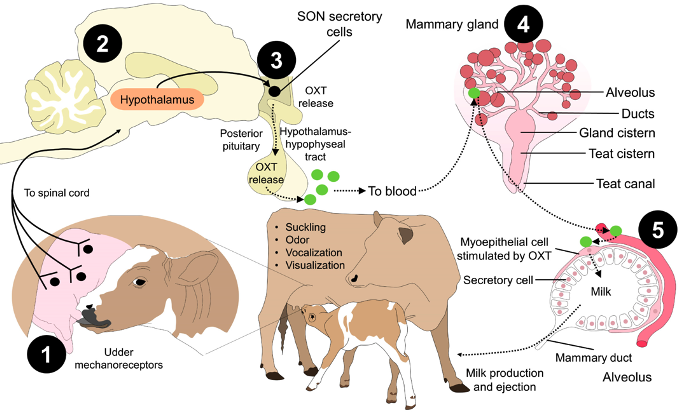

Oxytocin

- This hormone causes muscle contraction to expel the baby and responsible for milk let down. Therefore also known as Milk Let Down Hormone.

- It is synthesized by hypothalamus of brain and then transferred to the posterior pituitary gland.

-

Lactogenesis: The process by which the mammary gland develops the ability to secrete milk is known as

Lactogenesis. -

Prolactin

- It stimulate milk production.

- It improves protein and lactos content in milk.

- It is secereted from anterior pituitary gland.

-

Adrenalin:

- When miltch animal is excited and disturbed during milking process, adrenalin hormone is released which inhibits milk ejection primarily by reducing blood flow to the gland so that sufficient concentrations of oxytocin cannot reach the receptors.

- This reduce the milk secretion.

- This is also known as Hormone of Fight or Flight.

Colostrum

- Colostrum is the first form of mammary gland secretion that is released by the mammary glands after giving birth.

- It lasts for first 3 to 5 days after calving.

- It changes rapidly in successive milking and become normal milk in about 5 days after calving.

- The protein content of colostrum is 4-5 times that of normal milk.

- Normal milk has 3.5 to 4 % protein while cow’s colostrum has 21% protein and buffalo colostrum has 23% protein.

- Colostrum is rich in globulins which serve as the carrier of antibodies to protect the calves against disease.

Physical properties of Milk

Colour

- Milk is a white liquid.

- Yellow colour of milk is due to presence of

Carotene. - Buffalo milk is whiter than cow milk because carotene is converted into color less

vitamin A.

Milk Fat

- Milk Fats are the most variable constituent of milk.

- It is a carrier of the fat – soluble vitamins A, D, E and K. The short chain fatty acids are unique of milk lipids and are digested and absorbed quickly.

- Polyunsaturated fatty acids (PUFA) is of great nutritional importance in Milk.

Oil in watertype of emulsion.

Viscosity

- Viscosity of the whole milk at 25°C is about 2.0 cP.

Freezing and Boiling Points

- The freezing points of cow and buffalo milk vary from -0.512 to -0.572 °C and from -0.521 to -0.572 °C respectively.

- The boiling point of milk is

100.17 °C.

Acidity and pH

- Freshly drawn milk has pH value in the range of

6.5 to 6.7(slightly acidic).

Water

- Fresh milk contains

84 – 87%water.

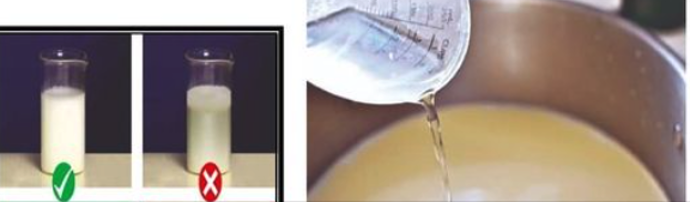

Milk Purity Test

Detection of Water

- Water is a most common adulterant, and its presence can be detected by testing the freezing point of milk. The official method of AOAC assumes a freezing point for normal milk of -0.550 degree C.

- The presence of water can also be checked by the use of

lactometer.

Detection of Starch

- Place in a test tube about 3ml of well-mixed sample.

- Boil it by holding the tube over a flame.

- Allow cooling to room temperature.

- Add a drop of 1% iodine solution.

- Presence of starch is indicated by the appearance of a blue colour that disappears when the sample is boiled and reappears on cooling,

Detection of Buffalo milk in Cow milk

- The presence of buffalo milk in cow milk can be detected by Hansa test, which is based on immunological assay.

- A drop of supected milk after dilution with water (1:4) is treated with a drop of antiserum obtained by injecting buffalo milk proteins into rabbits.

- The characteristic precipitation reaction indicates the presence of buffalo milk.

Alkaline Phosphatase (ALP) Test

- Alkaline Phosphatase (ALP) is an enzyme naturally present in all raw milks, which is used as an indicator of proper milk pasteurization.

- Complete pasteurization will inactivate the enzyme.

- The test can also indicate if milk has been contaminated with raw milk after pasteurization.

- The Alkaline Phosphatase test can be utilized to identify whether milk has been properly pasteurized or if it was affected by raw milk following pasteurization.

More the intensity of yellow colour, more is the intensity of ALP enzyme in the milk

Principles of Milking

- Milking is defined as the critical and laborious process which involves hormonal reflex. The art of milking performed within 5-8 minutes.

- Normally milking is done twice a day.

- The cattle and buffaloes are exclusively maintained for milk production.

- If the calf is allowed to suckle the complete quantity of milk it leads to digestive disturbances, enteritis, etc., usually milk is fed to calves depending upon the body weight of the calf the rate of

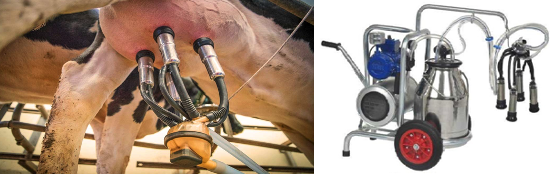

1/10th of the body weight during first week and1/15th the body weight during the second week. - Though milking is a laborious process, under present circumstances new innovation has been made to extract the milk from the udder. They are knonwn as Mechanical milkers or milking machines.

- The pulsation and intermittent vacuum and pressure are basic concepts of the milking machines.

- The advantages of the milking machines are that a large quantity of milk can be harvested in a shorter duration with the help of unskilled personnel.

- The major portion of the work of a dairy man is from milking to disposal of the milk. Nearly 65% of the time is to be devoted for the management in connection with milking and marketing of milk.

Principles of Milking: 3

- Natural Technique (Calf Suckling)

- Manual Technique (Hand Milking)

- Mechanical Technique (Machine Milking)

Natural Technique

- This method calf is able to draw the milk from the udder. To extract the milk the calf presses the teat with the tongue and pallet on the other side.

- The tongue encircles the teat and vacuum is created in the mouth by separating the jaws and retracting the tongue nearly 100 – 200 alternating cycles may be observed per minute. A calf’s suckling is the best method of evacuating the milk with least damage to the delicate tissue of mammary glands.

- The art of milking is a cycle 1. Active Phase 2. Restive Phase

I. Active Phase

- Creation of vacuum in the teat canal.

- Pressure is applied over the teat canal.

- The base of the teat is apparently occluded with the help of the tip of the tongue with the idea to prevent the back flow of the milk into the gland cistern when the pressure is applied which is followed by restive phase.

2. Restive Phase

- At this stage 20 mm Hg pressure is created at the teat end in the phase both active and restive phase are alternated and it has been scientifically proved that the amount of pressure applied over the teat canal:

- By calf is 535 mm Hg

- Hand milking is 310 mm of Hg

- Mechanical milking is in the range of 350 mm - 400mm Hg

- In the case of buffalos 400mm of Hg of pressure is applied but in the case of cattle it can be restricted to 360-380mm of Hg.

- It has been proved that cycling rate during nursing is twice as fast as hand or machine milking.

- Thus the difference along with increased cycling rate facilitates and explains the removal of milk from the udder at a faster rate by a calf when compared to hand or machine milking.

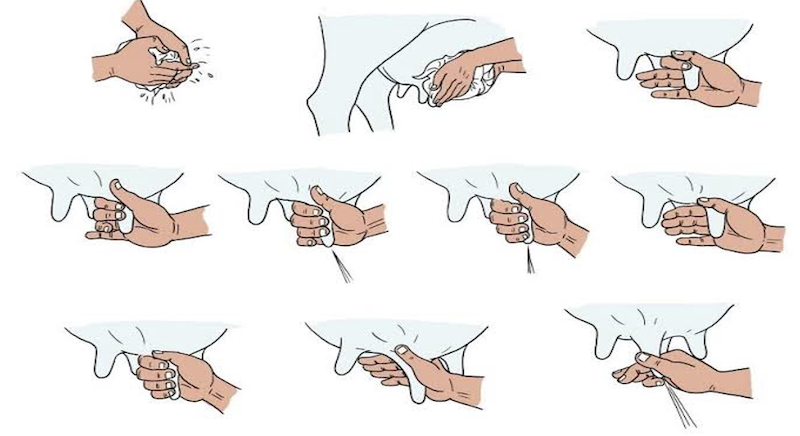

Hand milking

- It is commonly practiced in the harvesting of milk. In order of milking of various teats also differ.

- Strip Cup:

- It is a device with four circular plates for each quarter which has the quantity of milk normally first few strip of milk are drawn in the respective circles to assess the physiological status of the udder.

- If there is any change in color, consistency appearance, etc., the milk should be drawn at the end so as to prevent spreading the disease from one quarter to other.

- Prevention of Kicking of the cow:

- Application of milk man’s rope

- Anti-cow kicker

Methods of Manual Milking

- Fisting (Full hand method)

- Knuckling

- Stripping

Fisting

- In this method the whole teat is held first with the thumb and the index finger encircling the base of the teat.

- The base of the teat is closed by the ring formed by the finger, so that the milk that is trapped in the teat canal cannot slip back into the gland cistern.

- Simultaneously the teat is squeezed between the hollow of the palm and with the middle, ring and index finger. The process is repeated in succession.

- In this method teats are grasped with all the five fingers and pressed them against the palm. Therefore this method is known as

full hand method.

- It is the best method of hand milking because is causes lest damage to teats.

Knucking Method

- Many milkers tend to bend their thumb against the teat canal and drag the milk out.

- This practice should be avoided as it is injurious to the teat though most of the milkmen follow knuckling method.

Stripping

- This method is followed where the length of the teat is small; it is normally practiced towards the

end of milkingin order to evacuate the milk completely. - The last drawn milk is called stripping which is rich in fat content.

- The process of stripping should be done in quick succession otherwise the animal will become stripper where the letting down of milk is delayed.

Recommended is

full hand methodfollowed bystripping.

Dry and Wet type of Hand Milking

- In most of the place wet milking is practiced. The milkman moistens the hand with certain type of emollients like castor oil, or few strips of milk or even their own saliva.

- This should be avoided for the sake of cleanliness. If wet milking is practiced, the teats will look harsh and there is every possibility of development of cracks. Both the hands can be used for milking in continuous milking.

Frequency of Milking

- It depends upon quantity of milk yield. Under normal circumstances the quantity of milk is less than 10 litres/day

two timesmilking is followed when more than 10 litresthree timesmilking is followed. It has been observed and proved that three times milking improves milking 10-15%. - The factors that are to be considered during milking:

- Avoid excitement of the animal during and prior to milking. If the animal is excited then there is release of adrenaline and it will cause vasoconstriction.

- Prepare and collect all the milking equipments prior to milking.

- Milking operation should be continuous one. As far as possible exact time of milking is to be followed.

- Prepare the cow for milking.

- Complete the milking within 5-7 minutes.

- Use both hands for milking.

- Use correct method and type of milking.

- Weaned animals should not be milked with the calves nearby.

- Provide concentrate mixture at the time of milking.

- Remove the first few stripping for any possible abnormalities of milk.

- Group the animals 2 hours prior to milking.

- More than one milkman should milk a cow during the lactation so that any change in milkman will not affect / cause any problem in milking especially in the letting down process of lactating animals.

Machine Milking

- A calf and the machine do the harvesting of milk in a similar fashion. The function of the tongue, dental pallet and jaw movement of the calf is done by the inflation tube, pulsator and vacuum pump. Milk removal is largely dependent upon the differential pressure across the teat canal.

- The total differential pressure created by the milking machine is approximately 352 mmHg in the case of cattle and 400 mm Hg in the case of buffaloes. The pressure facilitates the expulsion of milk from the canal.

- It can extract 1.5 to 2 liter milk per minute.

- One or two animals can be milked simultaneously and the maximum of eight animals can be milked at a time.

- One milking machine for – 10 animals yielding 10 litres / day will be economical to maintain.

Explore More 🔭

🟢 https://www.youtube.com/watch?v=vAoZFuoKkDI

Merits

- Easy method of extracting milk.

- Does not require any skill.

- Keeping quality of milk is high.

- Chances of spreading of disease of the milk man to udder through milk are negligible.

- Time consumed is less.

Demerits

- Cost is high.

- Electricity is essential.

Clean Milk Production

- Both pre and post-secretory management of milk at the farm level should be focused upon for controlling the quality of milk.

- The post-secretory changes in milk are of paramount importance. Some of the vital factors responsible for good milk production that deserve immediate attention are type of farming, type of milk, impact on environment, farm waste disposal facilities, milking practices, procurement systems and inconsistent price policy and farmers’ education/training programmes.

- Milk once secreted becomes the target for transformation by a variety of host organisms at the farm itself. Hence, proper care must be taken regarding preservation of milk, protection of milk constituents, protection against high temperatures and natural calamity.

- Strict protocols are to be observed and implemented both in hand and machine milking. The microbiological quality deserves special attention for stringent export requirements for milk products in global market. The custodian of milk should never compromise on quality.

- Advantages of Clean milk production

- Protects the health of calves.

- Protects the health of consumers especially infants, growing children and aged people.

- The cleaner the milk longer in its keeping quality and flavor.

- Consumer will demand milk when confidence is developed on its wholesomeness.

- Sour and off flavored milk – not readily marketable.

Rural milk collection

- Milk is cooled to

4 °Cat primary chilling center before transporting to the milk plant. - Care should be exercised to bring the milk for chilling/processing within 3 hours of milking otherwise serious deterioration of milk takes place, which affects the quality of products.

- Milk may be collected from individual procedures either by the contractor or by forming village level cooperative societies.

References

- G.C. Banerjee: A Textbook of Animal Husbandry

- https://www.dairyknowledge.in

- https://buffalopedianew.cirb.res.in/godavari/

- https://nbagr.icar.gov.in/

- https://www.nddb.coop/

- Wikipedia

Which of the following statment is wrong?

- Milk is the lacteal secretion of the mammary glands of animals. It is obtained generally from the cow or the buffalo during the period following at least 72 hours after calving or until the milk is colostrum free.

- Milk is a white opaque fluid in which fat is present as an

emulsion, protein and some mineral matters incolloidal suspension, and lactose together with some minerals and soluble proteins intrue solution.

Composition of Milk

- Milk proteins composition:

80% Casein Proteinand20% Whey Protein. - Lactose of milk can be digested by lactase enzyme in human body.

- Milk is sweet because of presence of

lactosesugar. - All 22 minerals considered essential to the human diet are present in milk.

- Milk is a poor source of Iron and Vitamin C. …

Become Successful With AgriDots

Learn the essential skills for getting a seat in the Exam with

🦄 You are a pro member!

Only use this page if purchasing a gift or enterprise account

Plan

- Unlimited access to PRO courses

- Quizzes with hand-picked meme prizes

- Invite to private Discord chat

- Free Sticker emailed

Lifetime

- All PRO-tier benefits

- Single payment, lifetime access

- 4,200 bonus xp points

- Next Level

T-shirt shipped worldwide

Yo! You just found a 20% discount using 👉 EASTEREGG

High-quality fitted cotton shirt produced by Next Level Apparel