🍧 Processing of Milk

Milk processing and Milk Products

Which of the following statment is wrong?

👉🏻 Milk Processing includes following process:

- Clarification

- Pasteurization

- Homogenization

- Fortification

- Dehydration

Clarification

- Clarification is the removal of small particles, straw, hair etc. from milk.

- Bactofugation is the Centrifugal separation of microorganisms from milk.

Thermal processing

- The main purpose of heat treatment of milk is to render it safe for human consumption and to enhance its shelf life.

- Thermal processing is an integral part of all operations/processes of milk and milk products manufacturing units.

👨🏻🎓 Why Thermal Process?

- Milk contains some microorganism when drawn from the udder that number increases during subsequent handling.

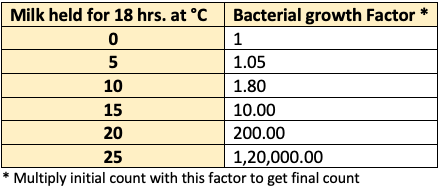

- The common milk microorganisms grow best between 20 and 40°C bacteriological growth is invariably accompanied by deterioration in market quality due to development of off flavor acidity etc.

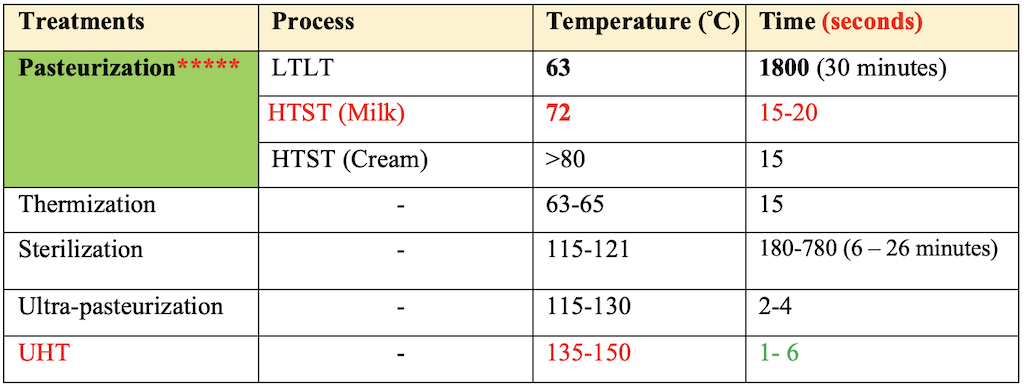

Effect of storage temperature on bacterial growth in milk

Pasteurization

- The term pasteurization has been coined after the name of Louis Pasteur of France (1860) who demonstrated that heating wine at 122 to 140°F (50 – 60°C) killed the spoilage organism and helped in its preservation.

- Although Louis Pasteur pioneered studies of heat treatment for preservation, pasteurization of milk was attributed to Dr. Soxhlet of Germany in 1888.

- The purpose of pasteurization of milk is to destroy most of the pathogenic microorganism’s disease-causing bacteria.

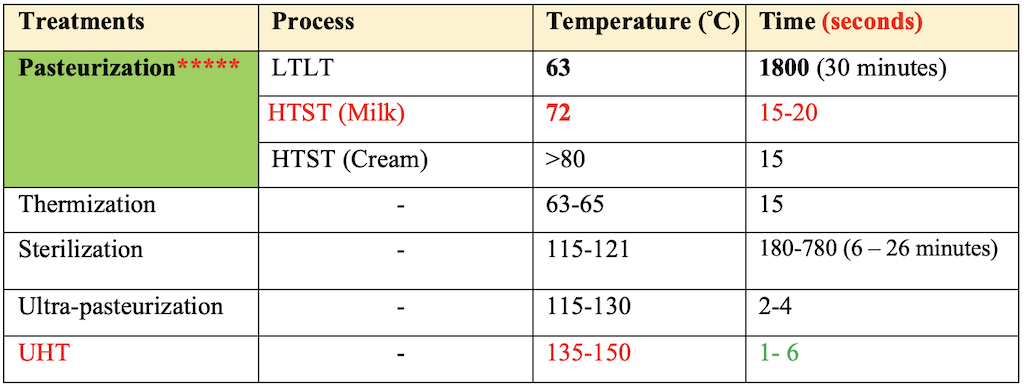

Pasteurization of Milk

- It is the process of heating every particle of milk or milk products, in properly designed and operated equipment to specified temperature and holding at that temperature for specified period of time followed by immediate cooling and storing at low temperatures.

- Pasteurization can be achieved either by holding method (batch process) or continuous process.

- Under batch process the milk is heated to

63°Cfor30 minutesin a double jacketed vat. Heating and cooling is done by spraying or circulating hot water /steam of chilled water between the inner and outer jacket of the vessel. The milk is kept gently agitated mechanically to ensure uniform heating/cooling. The process is called Low Temperature Long Time (LTLT) method. This method is suitable for small quantities ranging from 200-1000 liter requiring low initial cost of equipment. - High Temperature Short Time (HTST) treatment for pasteurization of milk refers to heating every particle of milk in a continuous flow to a minimum of

72°Cfor at least15 secondsfollowed by immediate cooling to 4°C. The entire process is automated and is ideal for large scale handling of 5,000 liters or higher. - Advantages

- Pasteurization renders milk safe for consumption

- It destroys all the common disease producing organism eg. TB, Typhoid, Diptheria, etc. which may be present in milk.

- Pasteurization destroys approximately 99% of all bacteria and most of the yeast and moulds.

- Keeping quality is improved facilitating easy transport of milk over long distances.

- Pasteurized milk or cream – desired type of ripening can be obtained more effectively.

- Pasteurization eliminates undesirable taints from milk.

- Products prepared from pasteurized milk are of more uniform quality.

- Natural flavor of milk is not affected by Pasteurization.

- Pasteurization destroy lipase enzyme / which is responsible for rancidity of milk.

Thermization

- This process consists of heating milk below pasteurization temperature to temporarily inhibit bacterial growth.

- The process is useful where it is not possible to immediately pasteurization all the milk and some of the milk needs to be stored for hours/days before further processing.

- The milk is heated to 63-65°C for 15 seconds and rapidly chilled to 4°C or below to prevent aerobic spore forming bacteria from multiplying after thermization. Thermization has favorable effect on spore forming bacteria to revert to vegetative state which are destroyed upon subsequent pasteurization.

Sterilization

- In this process milk or condensed milk packed in clean containers is usually subjected to high temperature (115-120°C) for 6 – 26 minutes.

- The containers may be tin cans (200-400 g capacity) for evaporated/sweetened condensed milk or glass bottle for milk.

- The process of heating and partial cooling is achieved in a rotary autoclave for batch production or hydrostatic tower for continuous production.

- In container sterilization is the original form of sterilization and is still used.

Ultra – pasteurization

- Its objective is to enhance or extend the shelf life of the product (milk) by 15 – 30 days.

- The fundamental principle is to reduce main causes of reinfection of the product during processing and packaging.

- This is achieved by heating milk to 115-130°C for 2-4 seconds and cooling it to below 4°C. This requires extremely high level of hygienic practices to be followed during production and maintenance of temperature lower than 4°C during distribution of such products. Ultra pasteurized products are packed in pre-sterilized containers aseptically and held refrigerated to achieve extended shelf life.

Ultra-high temperature treatment (UHT)

- It is a technique for preserving liquid food products by exposing them for brief intense heating. In short, the process is termed as UHT treatment.

- The heating temperature normally ranges from 135-150°C for 1-6 seconds.

- The process is continues, which takes place in a closed system that prevent the product from being contaminated by air-borne microorganisms.

- The product passes through heating and cooling stags in quick succession followed by aseptic filling as an integral part of the process.

- There exist two methods of UHT treatment indirect heating and cooling in heat exchangers and direct heating by steam injection or infusion of milk with steam and cooling by expansion under vacuum. UHT-treated products are packed aseptically in specially designed multilayer containers and can be stored at room temperature for extended period of time (2-6 months) without bacterial growth.

Homogenization

- Homogenization is done to prevent creaming, or the rising of fat to the top of the container of milk.

- It is mechanical treatment used to reduce diameter of the

fat globuleby a factor 10. That is size is reduced to 1/10 of their original size. - The process of homogenization permanently emulsifies the fine fat lobules by a method that pumps milk under high pressure through a homogenizer.

- Resulting in the milk that maintains more uniform composition with improved body and texture, a whiter appearance, richer flavor, & more digestible curd.

Fortification

- The addition of fat-soluble vitamins A and D to whole milk is optional but must for low-fat milk & non-fat milk.

- It is usually carried out before pasteurization.

- To increase the viscosity and appearance, as well as the nutritive value of low-fat milk.

- This addition allows milk to reach a 10% (versus 8.25% usually present), and it will state “protein fortified” or “fortified with protein” on the label.

Dehydration

- Dehydration is an important operation used by many dairy processors to extend the shelf life of milk and dairy products.

- Dehydration inhibits growth of bacteria, yeast and moulds through the removal of water. Modern technologies allow for the manufacture of milk powders with high nutritional value.

- Key technologies used by the dairy sector within the dehydration process include:

- Spray Drying: Pasteurized milk is first concentrated in an evaporator to approximately 50% milk solids. The resulting concentrated milk is then sprayed into a heated chamber where the water almost instantly evaporates, leaving fine particles of powdered milk solids.

- Drum Drying: Milk is applied as a thin film to the surface of a heated drum, and the dried milk solids are then scraped off. However, powdered milk made this way tends to have a cooked flavor, due to caramelization caused by greater heat exposure.

- Freeze Drying: Same as drum drying but involves freezing which retains more amount of nutrition.

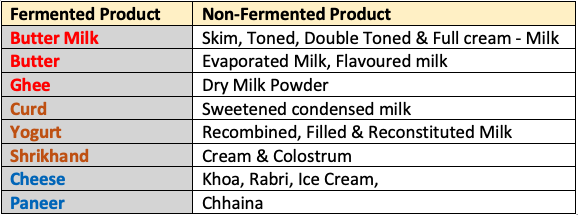

Milk Products

Non Fermented Milk Products

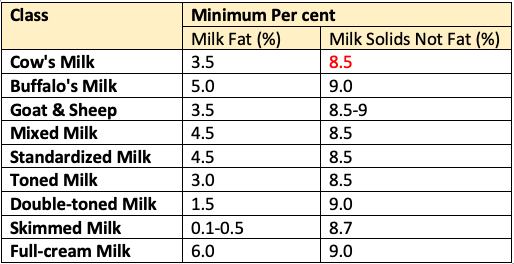

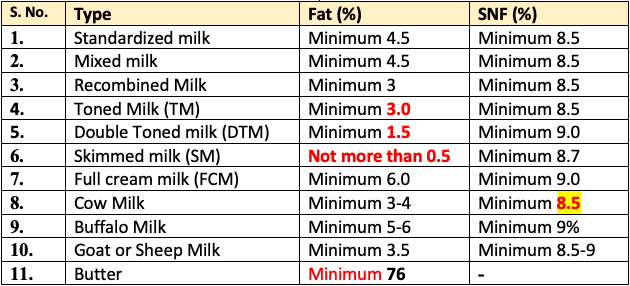

- According to the FSS Rules, 2011 (formerly PFA Rules)

- Buffalo Milk: The minimum milk fat is

5 – 6 %and minimum milk SNF is9%. - Cow Milk: Minimum milk fat is

3 – 4%and minimum milk SNF is8.5%. - Goat and Sheep Milk: Minimum milk fat is

3.5%and minimum milk SNF is8.5 - 9%. - Standardized Milk: Should contain minimum milk fat of 4.5% and minimum milk SNF of 8.5% throughout India.

- Recombined Milk: Means homogenized product prepared by mixing of milk fat, non-fat milk solids and water. It should contain minimum milk fat 3% and minimum milk SNF of 8.5%.

- Toned Milk:

- It should contain minimum milk fat

3%and minimum milk SNF of8.5%.

- Tonned mik is the brainchild of Dr. D. N Khurody who is credited with coining this name. Under his guidance, is was first produced in Mumbai city.

- Toned milk is a good option if you have high cholesterol levels or your body mass index, or BMI, is in a higher-than-healthy bracket. But don’t delete it from your diet entirely.

- It is a great option for people suffering from heart disease.

- It should contain minimum milk fat

- Double Toned Milk:

- It should contain minimum milk fat

1.5 %and minimum milk SNF of9 %.

- DTM is made from cow and/or buffalo milk by adding fresh skim milk or a mixture of water and skim milk or a mixture of water and skim milk powder and/or by removing fat by partial separation, or by doing both.

- It should contain minimum milk fat

- Skim Milk: It should contain minimum milk fat

0.5%and minimum milk SNF of8.7%.

- Full Cream Milk: Minimum

6% fatand 9% SNF.

- Buffalo Milk: The minimum milk fat is

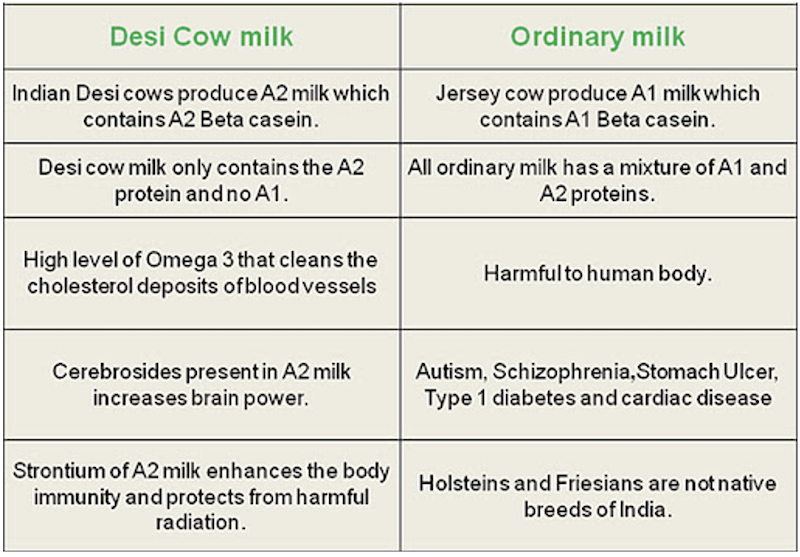

A1 and A2 Milk

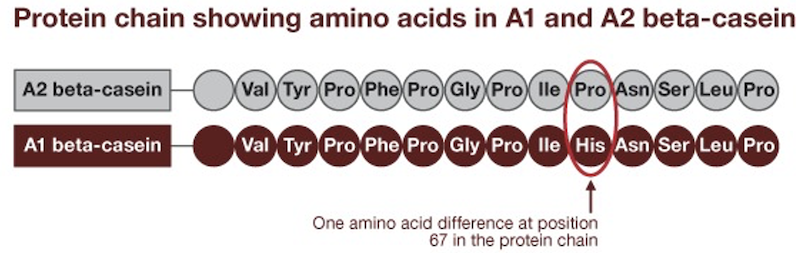

- The only difference between A1 and A2 is a difference in the 67th amino acid in the chain. At this position, A1 has a

histidineamino acid, while A2 has a proline amino acid. The entire basis of the supposed problem with A1 milk is its pesky histidine amino acid at position 67.

Khoa

- Concentrated Milk product.

- Khoa is made by simmering full-fat milk in a large, shallow iron pan for several hours over a medium fire. The gradual evaporation of its water content leaves only the milk solids.

FSSAI STANDARDS FOR DIFFERENT MILK

Fermented Milk Products

- Milk carbohydrates are fermented by bacterium Streptococcus lactis.

Curd

- Milk is boiled and cooled to 21 °C and bacteria called

- Lactobacillus thermophilus are mixed in it in the form of sourdough.

- This bacterium converts lactose into lactic acid.

Ghee

- Ghee is a clarified butter fat prepared from cow or buffalo milk.

- Ghee means the pure clarified fat derived solely from milk or curd or from cream to which no coloring matter or preservative has been added.

- Fat: 99 to 99.5%

- Moisture: Not more than 0.5%

- For purity of ghee

R.M. Test(Richard Maisel Test) is performed.

Yoghurt

- Yoghurt means a coagulated product obtained from milk by lactic acid fermentation through the action of Lactobacillus bulgaricus and Streptococcus thermophilus.

Shrikhand

- Shrikhand is a traditional sweet of the Indian subcontinent made from strained yogurt.

- It is a traditional dessert in Gujarati and Marathi cuisine.

Cheese

- Cheese is a dairy product produced in wide ranges of flavors, textures, and forms by coagulation of the milk protein casein.

- It comprises proteins and fat.

- During production,

milk is usually acidifiedand either the enzymes ofrennetor bacterial enzymes with similar activity are added to cause the casein to coagulate. - The solid curds are then separated from the liquid whey and pressed into finished cheese.

Types of Cheese

🟢 Explore More 🔭 https://youtu.be/QKae1k1BDdA

Paneer

- It is a fresh acid-set cheese common in cuisine of the Indian made from full-fat buffalo milk or cow milk.

- It is a non-aged, non-melting soft cheese made by curdling milk with a fruit- or vegetable-derived acid, such as lemon juice.

References

- G.C. Banerjee: A Textbook of Animal Husbandry

- https://www.dairyknowledge.in

- https://buffalopedianew.cirb.res.in/godavari/

- https://nbagr.icar.gov.in/

- https://www.nddb.coop/

- Wikipedia

Which of the following statment is wrong?

👉🏻 Milk Processing includes following process:

- Clarification

- Pasteurization

- Homogenization

- Fortification

- Dehydration

Clarification

- Clarification is the removal of small particles, straw, hair etc. from milk.

- Bactofugation is the Centrifugal separation of microorganisms from milk.

Thermal processing

- The main purpose of heat treatment of milk is to render it safe for human consumption and to enhance its shelf life.

- Thermal processing is an integral part of all operations/processes of milk and milk products manufacturing units.

👨🏻🎓 Why Thermal Process?

- Milk contains some microorganism when drawn from the udder that number increases during subsequent handling.

- The common milk microorganisms grow best between 20 and 40°C bacteriological …

Become Successful With AgriDots

Learn the essential skills for getting a seat in the Exam with

🦄 You are a pro member!

Only use this page if purchasing a gift or enterprise account

Plan

Rs

- Unlimited access to PRO courses

- Quizzes with hand-picked meme prizes

- Invite to private Discord chat

- Free Sticker emailed

Lifetime

Rs

1,499

once

- All PRO-tier benefits

- Single payment, lifetime access

- 4,200 bonus xp points

- Next Level

T-shirt shipped worldwide

Yo! You just found a 20% discount using 👉 EASTEREGG

High-quality fitted cotton shirt produced by Next Level Apparel